Mai kunna huhu shine mai kunnawa wanda ke amfani da matsa lamba na iska don fitar da budewa, rufewa ko daidaita bawul. Ana kuma kiransa da mai kunna numfashi ko na'urar numfashi. A wasu lokuta ana sanye take da wasu na'urori masu taimako na pneumatic. Waɗanda aka fi amfani da su sune na'urorin bawul da na'urorin hannu. Ayyukan ma'auni na bawul shine yin amfani da ka'idar amsawa don inganta aikin mai kunnawa ta yadda mai kunnawa zai iya cimma daidaitattun matsayi bisa ga siginar sarrafawa na mai sarrafawa. Ayyukan na'ura na hannu shine yin amfani da shi don yin aiki da bawul ɗin sarrafawa kai tsaye don kula da samar da al'ada lokacin da tsarin sarrafawa ya kasa saboda rashin wutar lantarki, rashin iskar gas, babu fitarwa na mai sarrafawa ko gazawar mai kunnawa.

Ƙa'idar Aiki na Pneumatic Actuator

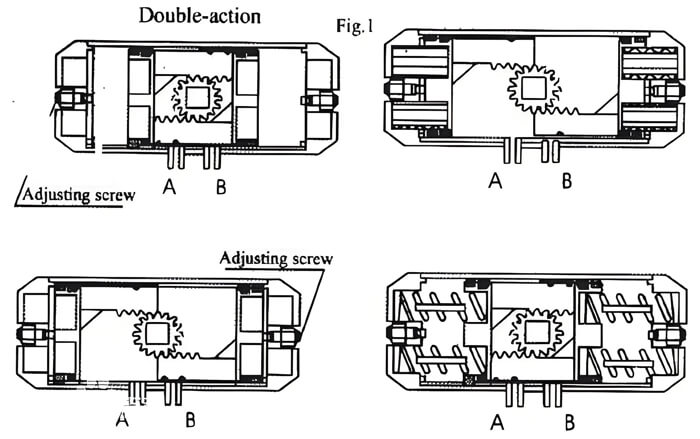

Lokacin da iskar da aka matsa ta shiga cikin mai kunna huhu daga bututun ƙarfe A, iskar tana tura pistons biyu don matsawa a layi zuwa iyakar biyu (ƙarshen kan silinda), kuma taragon da ke kan fistan yana motsa kayan a kan jujjuyawar juyi don juyawa digiri 90 counterclockwise, kuma an buɗe bawul ɗin. A wannan lokacin, ana fitar da iskar gas a ƙarshen ƙarshen pneumatic actuator daga bututun ƙarfe B. Akasin haka, lokacin da iskar da aka matsa ta shiga cikin iyakar biyu na mai kunnawa pneumatic daga bututun B, gas ɗin yana tura piston biyu don motsawa cikin layi a tsakiyar, kuma rack akan piston yana fitar da gear akan madaidaicin jujjuyawar juyi, digiri 90 yana jujjuya agogo. A wannan lokacin, ana fitar da iskar gas a tsakiyar mai kunna pneumatic daga bututun A. Abin da ke sama shine ka'idar watsawa na daidaitattun nau'in. Dangane da buƙatun mai amfani, ana iya shigar da mai kunna pneumatic tare da ka'idar watsawa sabanin daidaitaccen nau'in, wato, axis ɗin da aka zaɓa yana juya agogon hannu don buɗe bawul, kuma yana jujjuya agogon agogo don rufe bawul. A bututun ƙarfe na mai aiki guda ɗaya (nau'in dawowar bazara) mai kunnawa na pneumatic shine shigar iska, kuma bututun B shine ramin shayewa (ya kamata a shigar da bututun B tare da muffler). Mashigin bututun ƙarfe yana buɗe bawul ɗin, kuma ƙarfin bazara yana rufe bawul ɗin lokacin da aka yanke iska.

Ayyukan Pneumatic Actuator

1. Ƙarfin fitarwa da aka ƙididdigewa ko jujjuyawar na'urar pneumatic yakamata ya bi ka'idodin ƙasashen duniya da na abokin ciniki

2. A karkashin yanayi mara nauyi, ana shigar da silinda tare da matsa lamba na iska da aka ƙayyade a cikin "Table 2", kuma motsi ya kamata ya zama santsi ba tare da raguwa ko rarrafe ba.

3. A ƙarƙashin matsin iska na 0.6MPa, ƙarfin fitarwa ko ƙaddamar da na'urar pneumatic a cikin duka hanyoyin buɗewa da rufewa ba za su kasance ƙasa da ƙimar da aka nuna akan sunan na'urar pneumatic ba, kuma aikin zai kasance mai sassauƙa, kuma babu nakasar dindindin ko wasu abubuwan da ba a saba gani ba zasu faru a kowane bangare.

4. Lokacin da aka gudanar da gwajin hatimi tare da matsakaicin matsa lamba na aiki, yawan iska daga kowane gefen matsa lamba baya ba zai wuce (3 + 0.15D) cm3 / min (misali yanayin); Adadin iskar da ke fitowa daga murfin ƙarshen da fitarwa ba zai wuce (3 + 0.15d) cm3 / min ba.

5. Ana yin gwajin ƙarfin ƙarfi tare da sau 1.5 matsakaicin matsa lamba na aiki. Bayan kiyaye matsi na gwaji na mintuna 3, murfin ƙarshen Silinda da sassa na hatimi na tsaye ba a yarda su sami ɗigogi da nakasar tsari ba.

6. Yawan rayuwar aiki, na'urar pneumatic tana kwatanta aikin bawul ɗin pneumatic. A ƙarƙashin yanayin kiyaye ƙarfin fitarwa ko ƙarfin turawa a cikin duka kwatance, adadin buɗewa da rufewa ba zai zama ƙasa da sau 50,000 (zagayowar buɗewa ɗaya ba).

7. Don na'urorin pneumatic tare da hanyoyin buffer, lokacin da piston ya motsa zuwa matsayi na ƙarshe na bugun jini, ba a yarda da tasiri ba.

Fa'idodin Pneumatic Actuators

1. Karɓar ci gaba da siginar gas da fitarwa ta layi (bayan ƙara na'urar juyar da wutar lantarki/gas, zai iya karɓar ci gaba da siginar lantarki). Wasu na iya fitar da matsuguni na kusurwa bayan an sanye su da hannun rocker.

2. Akwai ayyuka masu kyau da marasa kyau.

3. Gudun motsi yana da girma, amma saurin zai ragu lokacin da nauyin ya karu.

4. Ƙarfin fitarwa yana da alaƙa da matsa lamba na aiki.

5. Babban dogara, amma ba za a iya kiyaye bawul ɗin bayan an katse tushen iska (ana iya kiyaye shi bayan ƙara bawul mai riƙewa).

6. Yana da m don gane segmented iko da shirye-shirye kula.

7. Sauƙaƙan kulawa da daidaitawa mai kyau ga yanayin.

8. Babban ƙarfin fitarwa.

9. Yana da aikin hana fashewa.

A cikin Summery

An tsara shigarwa da girman haɗin haɗin kai na masu kunna huhu da bawuloli bisa ga ka'idodin duniya ISO5211, DIN3337 da VDI/VDE3845, kuma ana iya musanya su tare da masu aikin pneumatic na yau da kullun.

Ramin tushen iska ya dace da ma'aunin NAMUR.

Ramin taro na ƙasa na mai kunna pneumatic (daidai da daidaitaccen ISO5211) murabba'i biyu ne, wanda ya dace da layin layi ko 45 ° shigarwa na bawuloli tare da sanduna murabba'i.

Lokacin aikawa: Fabrairu-16-2025