Kodi Pneumatic Ball Valve ndi chiyani

Mavavu a mpira wa pneumatic, omwe amadziwikanso kuti ma valve a mpira opangidwa ndi mpweya, ndi zigawo zofunika kwambiri m'makina osiyanasiyana olamulira madzimadzi m'mafakitale. Mapangidwe awo ophatikizika, kugwira ntchito mwachangu, ndi kusindikiza kodalirika kumawapangitsa kukhala abwino kwa ntchito zosiyanasiyana. Nkhaniyi ikufotokoza mwachidule ma valve a mpira wa pneumatic, kuphatikizapo mapangidwe awo, mfundo zogwirira ntchito, mitundu, ubwino, ntchito, kukhazikitsa, kukonza, ndi kuthetsa mavuto. Pamapeto pake, owerenga adzakhala ndi chidziwitso chokwanira cha mtundu wa valve wosunthika.

1. Chiyambi cha Pneumatic Ball Valves

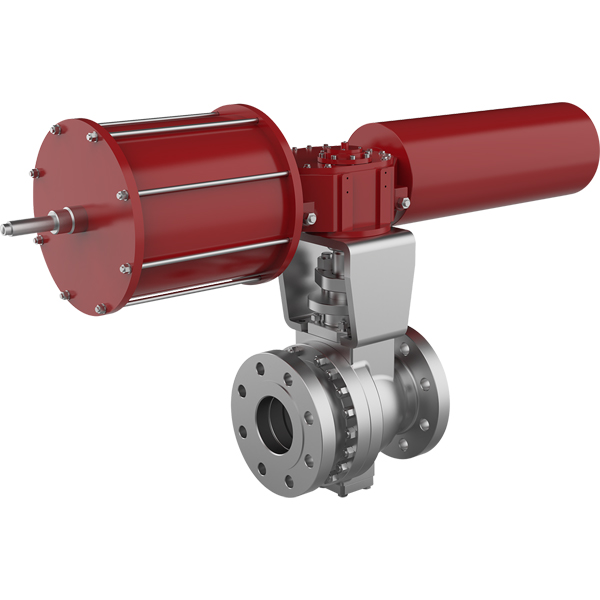

Ma valve a mpira wa pneumatic ndi ma valve omwe amagwiritsa ntchito mpweya woponderezedwa ngati gwero lamphamvu kuti athetse kutsegula ndi kutseka kwa valve. Amakhala ndi thupi la valavu ya mpira, mpira (monga chotsekera valavu), chowongolera pneumatic, ndi zina zowonjezera. Mpirawo uli ndi zozungulira-bowo kapena kudutsa mumzere wake, ndipo pozungulira mpirawo madigiri 90, kutuluka kumatha kutsegulidwa kwathunthu, kutsekedwa, kapena kupindika.

2. Kupanga ndi Mfundo Yogwirira Ntchito

Mapangidwe a valavu ya mpira wa pneumatic amachokera ku valavu yapadziko lonse koma ndi kusintha kwakukulu. Zigawo zikuluzikulu zikuphatikizapo:

Thupi la Vavu: Kawirikawiri amapangidwa ndi chitsulo chosapanga dzimbiri, chitsulo chosapanga dzimbiri, kapena zipangizo zina zoyenera, thupi la valve limakhala ndi mpira ndipo limapereka njira yoyendetsera.

Mpira: Chozungulira chomwe chili ndi dzenje lozungulira. Ikazunguliridwa ndi madigiri 90, dzenjelo limagwirizana ndi zolowera ndi zotuluka kuti zilole kuyenda, kapena zimasokonekera kuti zitseke kuyenda.

Pneumatic Actuator: Chigawochi chimasintha mpweya wothinikizidwa kukhala woyenda wamakina kuti uzungulira mpirawo. Zimapangidwa ndi silinda, pistoni, ndi ndodo yolumikizira.

Zisindikizo: Zisindikizo ndizofunikira kwambiri popewa kutayikira. Amapangidwa ndi zida za elastomeric kapena zitsulo ndipo amakhala pakati pa mpira ndi thupi la valve.

Mfundo yogwirira ntchito ndi yowongoka: pamene mpweya woponderezedwa umaperekedwa kwa actuator, pisitoni imasuntha, kuchititsa ndodo yolumikizira kutembenuza mpirawo. Kuzungulira uku kumayanjanitsa kapena kusalinganiza bowo ndi madoko olowera ndi potulukira, potero kuwongolera kutuluka.

3. Mitundu ya Pneumatic Ball Valves

Mavavu a mpira wa pneumatic amatha kugawidwa potengera njira zosiyanasiyana:

Kapangidwe: Zitha kukhala ziwiri, zidutswa zitatu, kapena chidutswa chimodzi. Ma valve awiri ndi osavuta kusamalira, pamene ma valve a chidutswa chimodzi amapereka ntchito yabwino yosindikiza.

Zosindikiza: Ma valve osindikizidwa ofewa amagwiritsa ntchito zipangizo za elastomeric kuti asindikize, zoyenera kugwiritsira ntchito mphamvu zochepa komanso zosawononga. Ma valve otsekedwa mwamphamvu amagwiritsira ntchito kusindikiza zitsulo ndi zitsulo, zoyenera pazitsulo zapamwamba komanso zotentha kwambiri.

Njira Yoyenda: Ma valve olunjika, atatu, ndi ngodya amapezeka, malingana ndi zofunikira za njira yoyendetsera.

Mtundu wa Actuator: Makina opanga kawiri amagwiritsa ntchito mpweya woponderezedwa kuti asunthire pisitoni mbali zonse ziwiri, pomwe makina osachita kamodzi amadalira kubwerera kwa masika mbali imodzi.

4. Ubwino wa Pneumatic Ball Valves

Ma valve a mpira wa pneumatic amapereka maubwino angapo kuposa mitundu ina ya mavavu:

Kugwira Ntchito Mwachangu: Kuzungulira kwa madigiri 90 kuti mutsegule kapena kutseka kwathunthu kumapangitsa kuti ntchitoyo ikhale yofulumira.

Compact Design: Mapangidwe ophatikizika amalola kuyika kosavuta m'malo olimba.

Kukanika kwa Madzi Ochepa: Mapangidwe athunthu amachepetsa kukana kwamadzimadzi, kuchepetsa kutsika kwamphamvu komanso kugwiritsa ntchito mphamvu.

Kusindikiza Kodalirika: Zisindikizo zapamwamba zimatsimikizira kutayikira kochepa, ngakhale kupsinjika kwambiri.

Kusinthasintha: Yoyenera pazofalitsa zosiyanasiyana, kuphatikiza madzi, mafuta, gasi, ndi mankhwala.

Kukonza Kosavuta: Zitsanzo zambiri zimalola kuti zikhale zosavuta kuzipinda zamkati kuti zisamalidwe.

5. Ntchito za Pneumatic Ball Valves

Ma valve a mpira wa pneumatic amagwiritsidwa ntchito kwambiri m'mafakitale osiyanasiyana chifukwa cha kusinthasintha kwawo komanso kudalirika kwawo:

Makampani a Petrochemical: Amagwiritsidwa ntchito m'mapaipi kuwongolera kuyenda kwamafuta, gasi, ndi mankhwala.

Chithandizo cha Madzi: Kuwongolera kayendedwe ka madzi ndi mankhwala opangira madzi m'mafakitale otsuka madzi.

Chakudya ndi Chakumwa: Onetsetsani zaukhondo ndikuwongolera kuyenda kwa zosakaniza ndi zinthu zopangidwa.

Makampani a Pharmaceutical: Amagwiritsidwa ntchito m'zipinda zoyera kuti aziwongolera kuyenda kwa media panthawi yopanga.

Zomera Zamagetsi: Yang'anirani kayendedwe ka nthunzi, madzi, ndi zoulutsira zina pamakina opangira magetsi.

Automation Systems: Zophatikizidwa m'makina opangira makina owongolera komanso kuyang'anira.

6. Kuyika ndi Kutumiza

Kuyika bwino ndi kutumiza ndikofunikira kuti ma valve a mpira wa pneumatic agwire bwino ntchito:

Kusankha Malo: Ikani valavu pamalo omwe amalola kuti azitha kupeza mosavuta komanso kugwira ntchito. Onetsetsani kuti valavu yaikidwa mopingasa kapena pakona yovomerezeka.

Kukonzekera Mapaipi: Tsukani payipi musanayike kuti zinyalala zisawononge zosindikizira za valve.

Kuyika Vavu: Tsatirani malangizo a wopanga kuti muyike valavu, kuphatikizapo ma torque a mabawuti ndi kusindikiza.

Connection Actuator: Lumikizani actuator ku valavu ndi mpweya. Onetsetsani kuti zolumikizira zonse ndi zolimba komanso zopanda kutayikira.

Kutumiza: Yesani valavu kuti mugwire bwino ntchito musanayigwiritse ntchito. Yang'anani kutayikira ndikuwonetsetsa kuti valavu imatsegula ndikutseka bwino.

7. Kusamalira ndi Kuthetsa Mavuto

Kusamalira nthawi zonse ndi kuthetsa mavuto kumakulitsa moyo wa ma valve a mpira wa pneumatic ndikuwonetsetsa kuti akugwira ntchito yodalirika:

Kuyendera: Yang'anani valavu pafupipafupi kuti muwone ngati yatha, yawonongeka, kapena yawonongeka. Yang'anani kutayikira kuzungulira zosindikizira ndi actuator.

Kupaka mafuta: Phatikizani magawo osuntha monga momwe wopanga amalimbikitsira kuti muchepetse kukangana ndi kuvala.

Kuyeretsa: Tsukani valavu ndi actuator nthawi zonse kuti muchotse litsiro ndi zinyalala.

Kusintha kwa Zisindikizo: Bwezerani zisindikizo zakale kapena zowonongeka mwachangu kuti musatayike.

Kusaka zolakwika: Ngati valavu ikulephera kugwira ntchito bwino, yang'anani mpweya, ntchito ya actuator, ndi ma valve internals kuti atseke kapena kuwonongeka.

8. Zochitika ndi Zamtsogolo

Makampani opanga ma valve a pneumatic akusintha mosalekeza kuti akwaniritse zosowa zamakampani. Zomwe zikuchitika zikuphatikiza:

Zida Zowonjezereka: Kupanga zida zatsopano zosindikizira ndi ma valavu kumawonjezera kukana kwa dzimbiri ndikuwonjezera moyo wa valve.

Mavavu Anzeru: Kuphatikizika kwa masensa ndi ukadaulo wolumikizirana kumathandizira kuyang'anira kutali ndikuwongolera magwiridwe antchito a valve.

Mphamvu Mwachangu: Mapangidwe amakonzedwa kuti achepetse kutsika kwamphamvu komanso kugwiritsa ntchito mphamvu, zomwe zimathandizira kukhazikika.

Kusintha mwamakonda: Opanga amapereka njira zothetsera chizolowezi kuti zigwirizane ndi zofunikira zenizeni zogwiritsira ntchito, kukonza ntchito ya valve ndi kudalirika.

Mapeto

Mavavu a mpira wa pneumatic ndizosunthika ndi zodalirika zigawo zikuluzikulu mu mafakitale kulamulira madzimadzi kachitidwe. Mapangidwe awo ophatikizika, kugwira ntchito mwachangu, ndi kusindikiza kodalirika kumawapangitsa kukhala abwino kwa ntchito zosiyanasiyana. Pomvetsetsa mapangidwe awo, mfundo zogwirira ntchito, mitundu, ubwino, ntchito, kukhazikitsa, kukonza, ndi kuthetsa mavuto, ogwiritsa ntchito angathe kuonetsetsa kuti ma valve awa ndi odalirika komanso ogwira ntchito m'mafakitale awo. Pamene teknoloji ikupita patsogolo, ma valve a mpira wa pneumatic adzapitirizabe kusinthika, ndikupereka magwiridwe antchito abwino, mphamvu zowonjezera mphamvu, ndi zosankha zosinthika kuti zigwirizane ndi kusintha kwa ntchito za mafakitale.

Nthawi yotumiza: Apr-13-2025