Ama-valve ebholaaphakathi kwama-valve asetshenziswa kakhulu ezinhlelweni zokulawula uketshezi ezimbonini nezohwebo. Idizayini yazo elula, ukuqina, nokubekwa uphawu okuthembekile kuzenza zilungele izinhlelo zokusebenza ezidinga ukuvalwa okusheshayo noma ukulawulwa kokugeleza. Phakathi kwezinhlobo ezahlukene zama-valve ebhola,ama-valve ebhola echwebeni agcwelezigqame ngomklamo wabo oyingqayizivele kanye nezinzuzo zokusebenza. Kulesi sihloko, sizohlola ukuthi iyini i-valve yebhola egcwele yembobo, ihluke kanjani kuma-valve embobo encishisiwe, izici zayo zokusebenza ezibalulekile, kanye nezinhlelo zokusebenza ezivame kakhulu.

Iyini i-Ball Valve

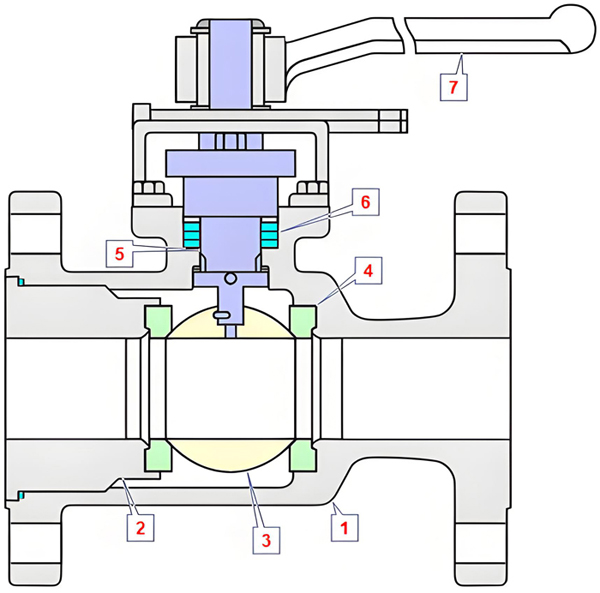

I-valve yebholaiyivalvu yokujika kwekota esebenzisa ibhola elingenalutho, elijikelezayo elinebhore (imbobo) phakathi nendawo ukuze lilawule ukugeleza koketshezi. Lapho i-valve ivuliwe, ibhobo liqondana nepayipi, livumela uketshezi ukuba ludlule. Ukuzungezisa ibhola ngamadigri angu-90 usebenzisa isibambo noma i-actuator kuvala i-valve, kuvimbele ukugeleza. Ama-valve ebhola ayaziwa ngawo:

- Ukusebenza okusheshayo(vula/vala ngemizuzwana).

- Ukubekwa uphawu kabili(ukugeleza kungaya kunoma iyiphi indlela).

- Ukwehla kwengcindezi ephansilapho ivuliwe ngokugcwele.

- Ukuqinaezindaweni ezinomfutho ophezulu noma izinga lokushisa eliphezulu.

Ama-valve ebhola ahlukaniswa ngosayizi wembobo, ukwakheka, nezinto ezibonakalayo. Iusayizi wetheku-ebhekisela kububanzi bobhore-idlala indima ebalulekile ekunqumeni umthamo wokugeleza kwe-valve kanye nokwehla kwengcindezi.

Iyini i-Full Port Ball Valve

Ai-valve yebhola ye-port egcwele(ebizwa nangokuthi ai-valve yebhola egcwele) yakhelwe ngobubanzi obuyibhore obufana neI-diameter yangaphakathi (ID) yepayipi elixhumayo. Isibonelo, uma i-valve ifakwe epayipini lama-intshi angu-4, isibhobo se-valve yebhola lembobo egcwele izokala amayintshi angu-4. Lo mklamo uqeda imikhawulo yokugeleza, uqinisekisa ukwehla kwengcindezi encane kanye nokusebenza kahle kokugeleza okukhulu.

Izici Ezisemqoka Zama-Full Port Ball Valves:

- Usayizi Bore:Ifanisa ububanzi bangaphakathi bepayipi.

- Idizayini Yomzimba:Umzimba we-valve omkhulu uma uqhathaniswa nama-valve embobo ancishisiwe ukuze kuhlaliswe ibhola elinosayizi ogcwele.

- Ukusebenza kahle kokugeleza:Cishe ukulahlekelwa yingcindezi uma ivuleke ngokuphelele.

- Izicelo:Ilungele amasistimu adinga ukugeleza okungakhawulelwe noma ukungulube (ukuhlanza/ukunakekela).

I-Port Ball Valve Egcwele iqhudelana neValve Yebhola Encishisiwe

Umehluko omkhulu phakathi kwembobo egcwele kanye nama-valve ebhola embobo encishisiwe ukuwousayizi bore:

| Isici | I-Port Ball Valve ephelele | I-Port Ball Valve Encishisiwe |

|---|---|---|

| I-Bore Diameter | Ifanisa i-ID yepayipi (isb, 4″ valve = 4″ ID) | Incane kune-ID yepayipi (isb, 4″ valve = 3″ ID) |

| Ukwehla Kwengcindezi | Okuncane kuya kokunye | Iphakeme ngenxa yomkhawulo wokugeleza |

| Amandla Okugeleza | Ubuningi | Kwehliswe ngo-20–50% |

| Valve Usayizi & Isisindo | Enkulu futhi esindayo | Ihlangene futhi ingasindi |

| Izindleko | Phezulu | Phansi |

| Izinhlelo zokusebenza | Ukugeleza okuphezulu, izingulube, ama-slurries | Inhloso evamile, amasistimu angabizi kakhulu |

Ungakhetha Nini Amavalvu Ebhola Embobo Egcwele:

- Amasistimu adingekayoukugeleza okungavinjelwe(isib. ukuvikela umlilo, ukuphakelwa kwamanzi).

- Amapayipi adingayoukungulube(imishini yokuhlanza idlule kulayini).

- Ukuphathauketshezi lwe-viscous, ama-slurries, noma imidiya elimazayo.

Ungakhetha Nini Ama-valve Embobo Encishisiwe:

- Amaphrojekthi agxile kwisabelomali ngeizidingo zokugeleza okumaphakathi.

- Amasistimu lapho isikhala noma isisindo siyisithiyo.

Izici Ezisebenzayo Zamavalvu Ebhola Lembobo Egcwele

1.Umkhawulo Wokugeleza Kweziro

I-bore enosayizi ogcwele iqinisekisa ukuthi uketshezi lugeleza luqonde ku-valve ngaphandle kwesiyaluyalu noma ukulahlekelwa kwengcindezi. Lokhu kubalulekile ezinhlelweni zokugeleza okuphezulu njengokusatshalaliswa kwamanzi noma amapayipi kawoyela.

2.Ukuhambisana Nengulube

Ama-valve embobo agcwele avumelaizingulube(imishini yokuhlanza noma yokuhlola) ukuze idlule epayipini ngaphandle kokuvinjwa, okuyenza ibaluleke ezimbonini zikawoyela negesi, amakhemikhali, namanzi angcolile.

3.Ukuvalwa kwe-Bidirectional

Amavalvu ebhola embobo egcwele avala ngokulinganayo ngokulinganayo kuzo zombili izinkomba zokugeleza, anikeze ukuguquguquka ekwakhiweni kwesistimu.

4.Ukuqina ku-Harsh Media

Ukubhoboza okubushelelezi nokwakhiwa okuqinile (ngokuvamile kuyinsimbi engagqwali noma ama-alloys) amelana nokuguguleka okuvela emanzini abrazayo noma abolayo.

5.Ukugcinwa Okulula

Ama-valve amaningi echweba agcwele afaka aumklamo wokuhlukanisa umzimba, okuvumela ukufinyelela okulula ezingxenyeni zangaphakathi ukuze zihlanzwe noma zilungiswe.

Iyini i-Full Port Ball Valve esetshenziselwa

Amavalvu ebhola embobo agcwele asetshenziswa ezimbonini lapho ukugeleza kahle, ukugwaza, noma ukuhambisana kwemidiya kuyinto ehamba phambili:

1.Amapayipi Kawoyela Negesi

- Ukuthutha uwoyela ongahluziwe, igesi yemvelo, noma imikhiqizo ecolisisiwe.

- Ukuvumela ukugxumeka kwengulube ukuze kuhlolwe futhi kulungiswe amapayipi.

2.Amanzi & Wastewater Systems

- Amanethiwekhi okuphakelwa kwamanzi kamasipala.

- Ukuphathwa kwe-slurry ezindaweni zokuhlanza indle.

3.Ukucubungula Amakhemikhali

- Ukudlulisa amakhemikhali e-viscous noma abrasive (isb., ama-polymer, ama-asidi).

4.Amasistimu okuvikela umlilo

- Ukuqinisekisa ukugeleza kwamanzi amaningi ngesikhathi sezimo eziphuthumayo.

5.Ukukhiqiza Amandla

- Amasistimu amanzi okupholisa ezitshalweni zenuzi noma ezishisayo.

6.I-Marine & Shipbuilding

- Ukudluliswa kwamafutha kanye nokuphathwa kwamanzi e-ballast.

Isiphetho

A i-valve yebhola ye-port egcweleiyi-valve esebenza kahle kakhulu eyenzelwe izinhlelo ezidinga kakhuluukugeleza okungakhawulelwe, amandla okuzingulube, nokulahlekelwa kwengcindezi encane. Nakuba inkulu futhi ibiza kakhulu kune-valve yasechwebeni encishisiwe, izinzuzo zayo ezintweni ezibalulekile—njengamapayipi kawoyela, ukuvikela umlilo, nokuphatha udaka—iyenza ibaluleke kakhulu. Ngokuqonda umehluko phakathi kwembobo egcwele kanye nama-valve ebhola lembobo ancishisiwe, onjiniyela nabaqhubi bangakhetha i-valve elungile ukuze kuthuthukiswe ukusebenza kahle, ukunciphisa izindleko zokusebenza, nokwelula isikhathi sokuphila kwesistimu.

Isikhathi sokuthumela: Mar-23-2025