I-actuator yomoya i-actuator esebenzisa umfutho womoya ukushayela ukuvuleka, ukuvala noma ukulawulwa kwe-valve. Ibuye ibizwe ngokuthi i-actuator yomoya noma isisetshenziswa somoya. Ama-actuator we-pneumatic kwesinye isikhathi ahlomelwe ngamadivaysi athile asizayo. Okuvame ukusetshenziswa ama-valve positioners kanye ne-handwheel mechanisms. Umsebenzi we-valve positioner ukusebenzisa isimiso sempendulo ukuze kuthuthukiswe ukusebenza kwe-actuator ukuze i-actuator ikwazi ukuthola ukuma okunembile ngokuvumelana nesignali yokulawula yesilawuli. Umsebenzi womshini wesondo lesandla ukuwusebenzisela ukusebenzisa ngokuqondile i-valve yokulawula ukugcina ukukhiqizwa okuvamile lapho isistimu yokulawula yehluleka ngenxa yokuphela kukagesi, ukuphela kwegesi, akukho okukhiphayo kwesilawuli noma ukwehluleka kwe-actuator.

Isimiso sokuSebenza se-Pneumatic Actuator

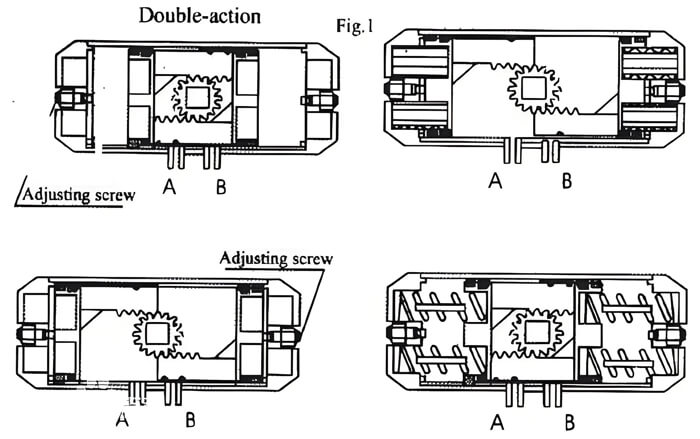

Lapho umoya ocindezelwe ungena ku-activator ye-pneumatic usuka ku-nozzle A, igesi iphusha ama-piston aphindwe kabili ukuze ahambe ngokulandelana emaphethelweni womabili (i-cylinder head end), futhi irack ku-piston ishayela igiya ku-shaft ejikelezayo ukuze ijikeleze ama-degree angu-90 ngokuphambene newashi, futhi i-valve ivuliwe. Ngalesi sikhathi, igesi emikhawulweni yomibili ye-actuator yomoya iyakhishwa ku-nozzle B. Ngokuphambene, lapho umoya ocindezelwe ungena emikhawulweni emibili ye-actuator yomoya usuka ku-B nozzle, igesi iphusha i-piston ephindwe kabili ukuze ihambe ngokulandelana phakathi nendawo, futhi irack ku-piston ishayela igiya ku-shaft ejikelezayo, futhi i-valve ivaliwe ukuze ijikeleze. Ngalesi sikhathi, igesi ephakathi kwe-actuator yomoya iyakhishwa ku-A. Okungenhla umgomo wokudlulisela wohlobo olujwayelekile. Ngokwezidingo zomsebenzisi, i-actuator ye-pneumatic ingafakwa ngesimiso sokudlulisela esiphambene nohlobo olujwayelekile, okungukuthi, i-axis ekhethiwe izungeza ngokwewashi ukuze ivule i-valve, futhi ijikeleze ngokuphambene newashi ukuze ivale i-valve. Umbhobho ongu-A we-single-acting (uhlobo lokubuyisela entwasahlobo) i-pneumatic actuator iyisimboli somoya, kanti imbobo engu-B iyimbobo yokukhipha umoya (imbobo engu-B kufanele ifakwe nesifihli). I-A nozzle inlet ivula i-valve, futhi amandla asentwasahlobo avala i-valve lapho umoya unqanyulwa.

Ukusebenza kwe-Pneumatic Actuator

1. Amandla okukhiphayo alinganiselwe noma i-torque yomshini womoya kufanele ahambisane nemithetho yamazwe ngamazwe neyekhasimende

2. Ngaphansi kwezimo zokungalayishi, isilinda siyafakwa ngomfutho womoya ocaciswe kokuthi “Ithebula 2″, futhi ukunyakaza kwawo kufanele kube bushelelezi ngaphandle kokugxumela noma ukunwabuzelayo.

3. Ngaphansi kokucindezela komoya okungu-0.6MPa, itorque ephumayo noma ukusunduza kwedivayisi yomoya kuzo zombili izikhombisi-ndlela zokuvula nezokuvala akufanele kube ngaphansi kwenani elikhonjiswe ku-nameplate yedivayisi yomoya, futhi isenzo sizovumelana nezimo, futhi akukho ukuguquguquka okuphakade noma ezinye izinto ezingavamile ezizokwenzeka kunoma iyiphi ingxenye.

4. Lapho ukuhlolwa kokuvala uphawu kwenziwa ngengcindezi ephezulu yokusebenza, inani lomoya ovuzayo ohlangothini ngalunye lwengcindezi yangemuva akufanele lidlule (3+0.15D)cm3/min (isimo esijwayelekile); inani lomoya ovuzayo kusukela kukhava yokugcina kanye neshafu yokuphumayo akufanele lidlule (3+0.15d)cm3/min.

5. Ukuhlolwa kwamandla kwenziwa izikhathi ezingu-1.5 zokucindezela okukhulu kokusebenza. Ngemuva kokugcina ingcindezi yokuhlola imizuzu emi-3, isembozo sokugcina isilinda kanye nezingxenye zokuvala ezimile azivunyelwe ukuthi zibe nokuvuza kanye nokuguqulwa kwesakhiwo.

6. Inombolo yokuphila kwesenzo, idivayisi ye-pneumatic ilingisa isenzo se-valve yomoya. Ngaphansi kwesimo sokugcina i-torque ephumayo noma umthamo we-thrust kuzo zombili izinkomba, inani lemisebenzi yokuvula nokuvala akufanele ibe ngaphansi kwezikhathi ezingu-50,000 (umjikelezo owodwa wokuvula wokuvala).

7. Kumadivayisi omoya anezinsimbi ze-buffer, lapho i-piston iya endaweni yokugcina ye-stroke, umthelela awuvunyelwe.

Izinzuzo ze-Pneumatic Actuators

1. Yamukela amasignali egesi aqhubekayo kanye nokuphumayo komugqa (ngemuva kokwengeza idivayisi yokuguqula ugesi/igesi, ingaphinda yamukele amasignali kagesi aqhubekayo). Abanye bangakhipha ukususwa kwe-angular ngemva kokuhlonyiswa ngengalo yerocker.

2. Kunemisebenzi yesenzo esihle nesibi.

3. Ijubane elihambayo liphezulu, kodwa ijubane lizohamba kancane lapho umthwalo ukhula.

4. Amandla okukhiphayo ahlobene nokucindezela kokusebenza.

5. Ukuthembeka okuphezulu, kodwa i-valve ayikwazi ukugcinwa ngemva kokuphazamiseka komthombo womoya (ingagcinwa ngemva kokwengeza i-valve yokugcina isikhundla).

6. Akulula ukubona ukulawula okuhlukene kanye nokulawula uhlelo.

7. Ukugcinwa okulula nokuvumelana nezimo endaweni ezungezile.

8. Amandla amakhulu okukhiphayo.

9. Inomsebenzi wokuvikela ukuqhuma.

Ehlobo

Ubukhulu bokufakwa nokuxhumeka kwama-actuator womoya namavalvu aklanywe ngokuvumelana nezindinganiso zamazwe ngamazwe ISO5211, DIN3337 kanye ne-VDI/VDE3845, futhi zingashintshaniswa nama-actuator avamile womoya.

Imbobo yomthombo womoya ihambisana nezinga le-NAMUR.

Imbobo engezansi yokuhlanganisa i-shaft ye-actuator yomoya (evumelana nezinga le-ISO5211) iyisikwele esiphindwe kabili, esilungele ukufakwa kwama-engeli angu-45 ° anezintambo zesikwele.

Isikhathi sokuthumela: Feb-16-2025