The leader of butterfly valves manufacturer in China

NSW VALVE is a leading butterfly valve manufacturer in China. You can purchase and consult the butterfly valve you are looking for here in one stop. Our centerline butterfly valve, triple eccentric butterfly valve, high performance butterfly valve, double eccentric butterfly valve will strictly control the quality of butterfly valve material, butterfly valve size and butterfly valve seal.

How to choose a butterfly valve

When selecting a butterfly valve, you need to consider the butterfly valve type, actuator, sealing material, end connection, butterfly valve material, size, fluid characteristics etc. NSW provides a selection guide to ensure that the butterfly valve performance matches the application requirements and improve system efficiency and reliability.

China, API 609, Triple Offset, Eccentric, Butterfly Valve, Wafer, Lugged, Flanged, Manufacture, factory, price, Caron Steel, Stainless Steel, A216 WCB, WC6, WC9, A352 LCB, A351 CF8, CF8M, CF3, CF3M, A995 4A, A995 5A, A995 6A. Pressure from Class 150LB to 2500LB.

China, API 609, Metal to Metal, Seat, Triple Offset, Eccentric, Butterfly Valve, Welded, Wafer, Lugged, Flanged, Manufacture, factory, price, Caron Steel, Stainless Steel, A216 WCB, WC6, WC9, A352 LCB, A351 CF8, CF8M, CF3, CF3M, A995 4A, A995 5A, A995 6A. Pressure from Class 150LB to 2500LB.

China, High Performance, Double, Eccentric, Butterfly Valve Wafer, Lugged, Flanged, Manufacture, Factory, Price, Carbon Steel, Stainless Steel, A216 WCB, WC6, WC9, A352 LCB, A351 CF8, CF8M, CF3, CF3M, A995 4A, A995 5A, A995 6A. Pressure from Class 150LB to 2500LB.

China, Concentric, Center line, Ductile Iron, Butterfly Valve, Rubber Seated, Wafer, Lugged, Flanged, Manufacture, Factory, Price, Carbon Steel, Stainless Steel, A216 WCB, WC6, WC9, A352 LCB, A351 CF8, CF8M, CF3, CF3M, A995 4A, A995 5A, A995 6A. Pressure from Class 150LB to 2500LB.

What is a butterfly valve

As an efficient and economical fluid control device, butterfly valves are widely used in industrial automation production. When choosing a suitable butterfly valve, we should not only consider its convenience of operation, but also ensure that its performance matches the application requirements. Beigao Technology Valve provides the following key guidelines for butterfly valve selection to help users make the right choice.

Understanding butterfly valve types

Central butterfly valve

also known as concentric butterfly valve is suitable for low pressure and low sealing requirements, such as water and air regulation. They generally have higher sealing performance and lower cost.

Double eccentric butterfly valve

suitable for medium pressure and certain applications that require a longer service life. The double eccentric design can reduce the friction between the valve seat and the butterfly plate, thereby extending the service life of the valve.

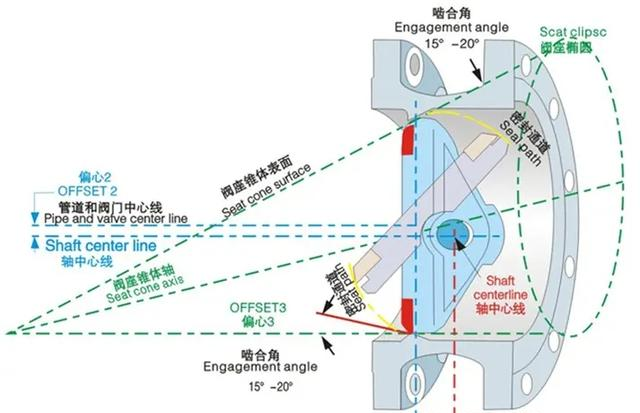

Triple eccentric butterfly valve

suitable for high pressure and harsh working conditions, such as high temperature or highly corrosive environment. The triple eccentric structure not only provides a tighter sealing effect, but also reduces the operating torque,improving the efficiency and reliability of the valve.

High performance butterfly valve

High performance butterfly valves are usually double eccentric butterfly valves with seats made of polymer composite materials such as RPTFE, which have unlimited life expectancy and very high chemical resistance.

Determine the operation of the butterfly valve

The operation of butterfly valves include manual, electric actuator, and pneumatic actuator.

Manual butterfly valve: Suitable for occasions where adjustments are not made frequently, and is operated directly by a handwheel or a wrench.

Therefore, it is suitable for occasions with small diameters and low operating frequency.

Electric butterfly valve: Suitable for applications that require remote control or automation systems. Electric butterfly valves can be easily integrated with other control devices to achieve high automation.

Pneumatic butterfly valve: Suitable for occasions that require fast response and/or large operating force, especially for emergency shut-off or safety-related applications.

Choose the correct butterfly valve seat sealing material

The sealing surface material of the butterfly valve can be divided into soft seal and metal hard seal according to the different media.

Soft seat butterfly valve

Soft seal is suitable for corrosive, highly toxic and highly hazardous media, it has Rubber seat butterfly valve, PTFE seat butterfly valve etc.

Metal seat butterfly valve

Metal seat seal is suitable for high temperature and high pressure working conditions. the butterfly valves seat can be F304, F316, Stellie, Monel etc.

Consider the butterfly valve end connection

The main end connect of butterfly valves include wafer type, flange type and clamp type.

Wafer butterfly valve

The wafer type connection is often used for small-diameter butterfly valves.

It is easy to install and has low cost, so it is widely used in small-diameter

pipelines.

Flange butterfly valve

The flange connection is suitable for large-diameter and high-pressure pipelines.

Lug butterfly valve

The lug butterfly valve is a special type of butterfly valve. Its notable feature is that the valve body has lugs on both sides, which is convenient for fixing between two pipe flanges by bolts.

This design makes the lug butterfly valve mainly used to cut off the medium in the pipeline.

Clamp butterfly valve

The clamp type connection is used for quick installation and is common in the food industry.

What working conditions are butterfly valves suitable for

Choosing a professional valve team to be responsible usually brings the best results. As a leader in Chinese butterfly valve manufacturers, NSW Valve has always adhered to professional technical guidance, high-end technical support, and perfect after-sales service as the standard to solve your one-stop purchasing needs.

Butterfly valves are widely used, mainly in various industrial fields, including control systems in the petroleum, chemical, metallurgical, water treatment, electric power, thermal and other industries. Butterfly valves are suitable for controlling or cutting off various fluid media, such as water, gas, oil, steam, etc., and are particularly suitable for low-pressure, large-diameter pipeline systems.

In terms of specific application occasions, butterfly valves can be used in the following situations:

Pipeline regulation or cut-off fluid: Butterfly valves are suitable for controlling or cutting off various fluid media, such as water, gas, oil, steam, etc.

Low-pressure, large-diameter pipeline: Butterfly valves are usually used in low-pressure, large-diameter pipelines. They have a simple structure, light weight, easy use, and little impact on the pipeline system.

Cargo storage tanks: Butterfly valves can be used to control the flow and pressure of liquid or gas in the storage tank, and are suitable for tank control systems in the chemical, petroleum and other industries.

Clean environment: Butterfly valves have a simple structure, good sealing, and are easy to clean. They are suitable for occasions with high requirements for clean environment, such as food, pharmaceutical and other industries.