Why Choose NSW Class 800 Gate Valve

One-stop Solution

Owing to a trusted supply network, we make unique valves with optimal performance for specific requirements.

Short Lead Time

For standard, OEM requests or urgent purchases, we complete your orders within 7 days. Customization-wise orders take a maximum of 30 days.

Value-Added Delivery

We add free accessories to orders before shipment, amounting to 10% of the total order volume. We can also include additional documents like product parameters, test results, and so forth.

Strong Manufacturing with R&D Culture

With a factory employing 5 production lines and cutting-edge machines, we easily produce up to 8,000 tons of valves annually continue to gain process in product design.

Class 800 Gate Valve Manufacturer

Discover high-quality Forged Steel Gate Valves, including API 602 standard. Trust our expertise as a leading Forged Steel Valve Manufacturer for reliable performance and durability.

Explore our range of Forged Steel Gate Valves and Flange Gate Valves, designed for durability and efficiency in fluid control systems. Ideal for any project.

Shop premium Bellows Forged Steel Gate Valves that ensure leak-proof performance and extended service life. Ideal for oil, gas, and water applications.

Find the best Cryogenic Forged Steel Gate Valves for your needs, featuring robust construction and precision engineering for safe and effective use.

Featured Class 800 Gate Valve

Prduct Range

Sizes: NPS 1/2, 3/4, 1, 1 1/4, 1 1/2, 2, 2 1/2, 3, 4 Inch.

Pressure Range: Class 150, 300, 600, 800, 900, 1500, 2500 LB.

Design Standard

End Connection: ASME B16.11 (SW), ASME B1.20.1 (NPT), ASME B16.5 (RF, RTJ)

Test & inspection: API 598

Also available per NACE MR-0175, NACE MR-0103, ISO 15848, API 624

Valve Structure

End Connection: SW, NPT, RF, RTJ or BW

Outside Screw & Yoke (OS&Y)

Bolted Bonnet, Welded Bonnet or Pressure Seal Bonnet

Valve Material

Be All-Inclusive

With a wide range of Forged Steel Valves, NSW valve can cooperate with any kind of client as shown below.

For Contractors and Subcontractors

When you are constructing or forming a valve system, you need a specific solution for your project requirements. NSW valve can assist you with our full-service support as well as system maintenance programs for all of your orders.

NSW valve has the customized solution and world-class services you require for any industry, including petroleum, petrochemical, and coal chemical producers. The experience we accumulated through years of providing performance-focused valves for practical applications ensures our valve solutions accomplish your project requirements.

For OEM/ODM Clients

To provide the right valve solutions for all your customers, you need a diverse range of industrial valves that fits their needs. Working with NSW valve gives you a rich selection of pump valves for any of your clients. You can also order a customized solution for specific projects.

With our one-stop shop for industrial valves and full-range custom options, NSW valve has the solutions you require for your business. When working with us, you have a team with rich qualifications and experience at your disposal as well as access to sufficient raw material inventory, automatic production, guaranteed quality, and fast lead time.

Raw Material Forging

Inspectors measure the size of our raw materials with Vernier calipers and thickness gauges to verify that the materials meet our procurement standards.

Incoming Material Inspection

MSS SP-55 and our drawing requirements regarding the exterior of all raw materials’ can be checked via a careful inspection by our trained staff.

Analysis of Chemical Element

Portable spectrometers allow our engineers to check the chemical composition of our raw materials to ensure the material meets our procurement technical specifications.

Mechanical Properties Test

Inspectors measure the size of our raw materials with Vernier calipers and thickness gauges to verify that the materials meet our procurement standards.

Dimensional Inspectionn

MSS SP-55 and our drawing requirements regarding the exterior of all raw materials’ can be checked via a careful inspection by our trained staff.

Performance Testing

Portable spectrometers allow our engineers to check the chemical composition of our raw materials to ensure the material meets our procurement technical specifications.

Hydraulic Testing

Inspectors measure the size of our raw materials with Vernier calipers and thickness gauges to verify that the materials meet our procurement standards.

Air Testing

MSS SP-55 and our drawing requirements regarding the exterior of all raw materials’ can be checked via a careful inspection by our trained staff.

Other Testing

Fugitive Emission Leakage Test

Fire Safety Test

Cryogenic Test

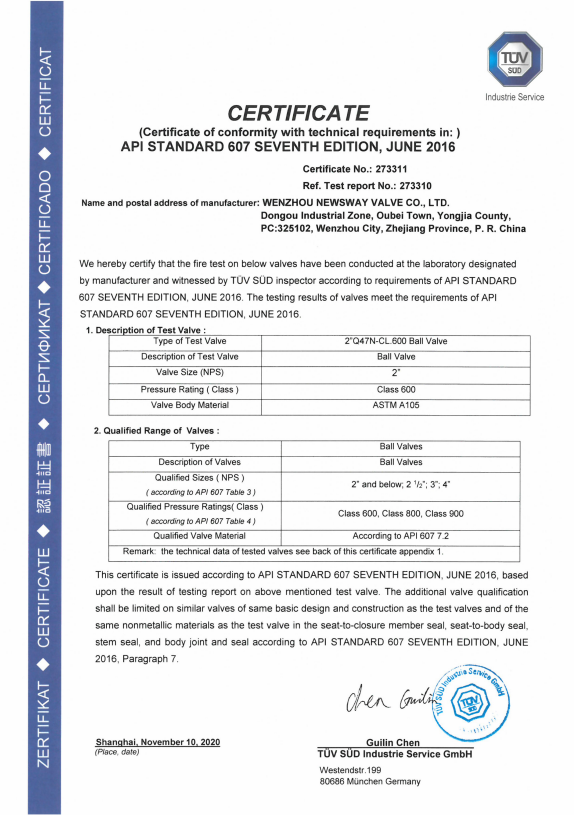

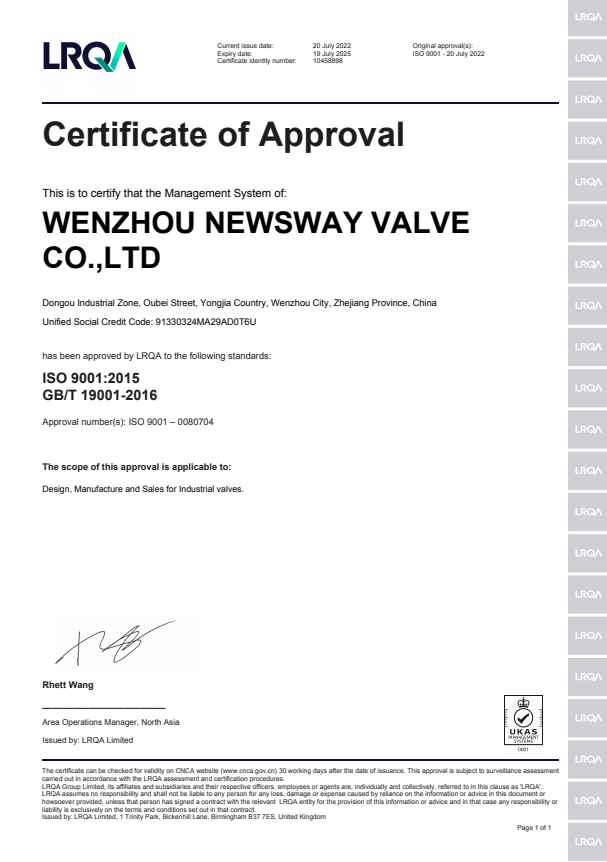

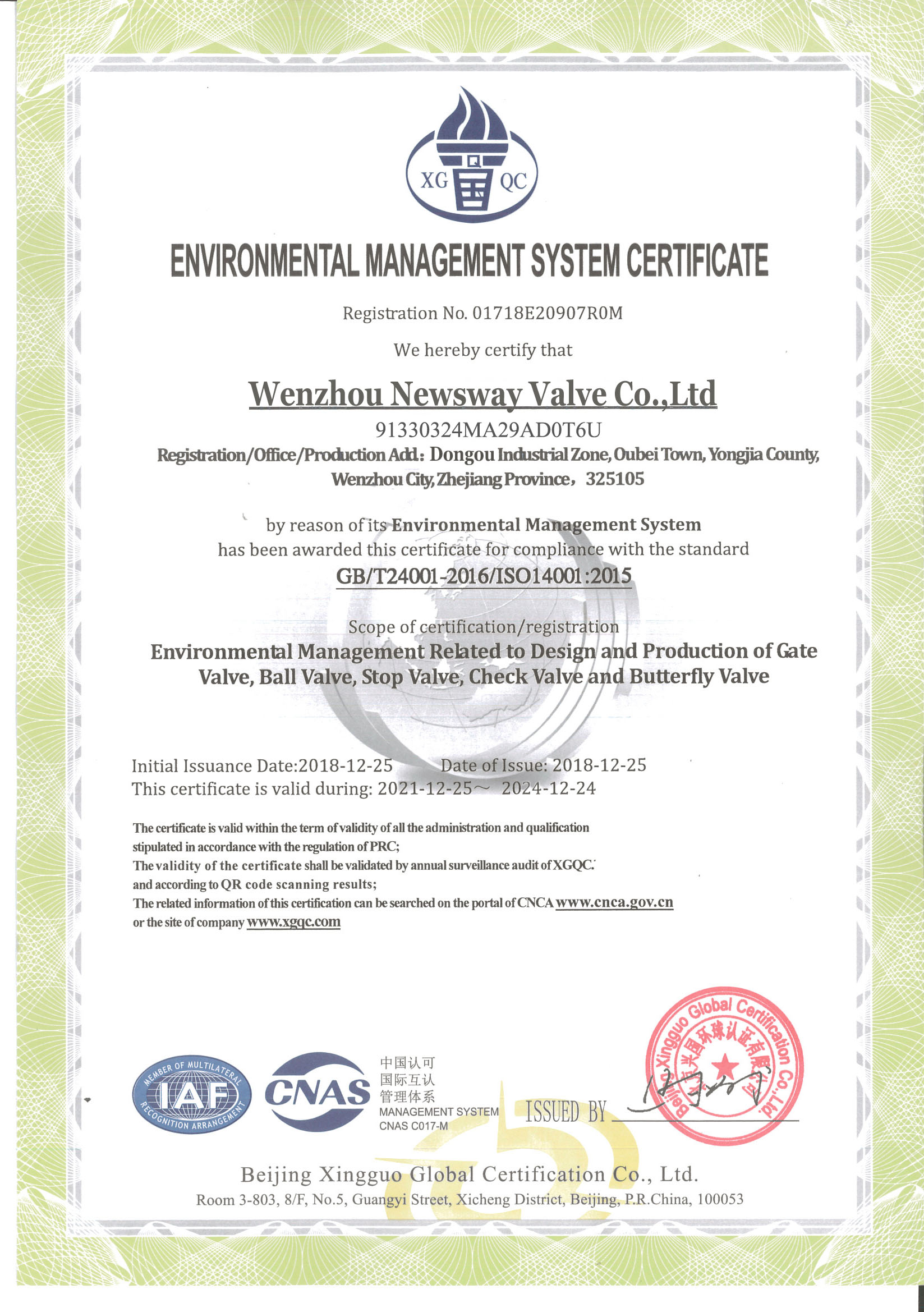

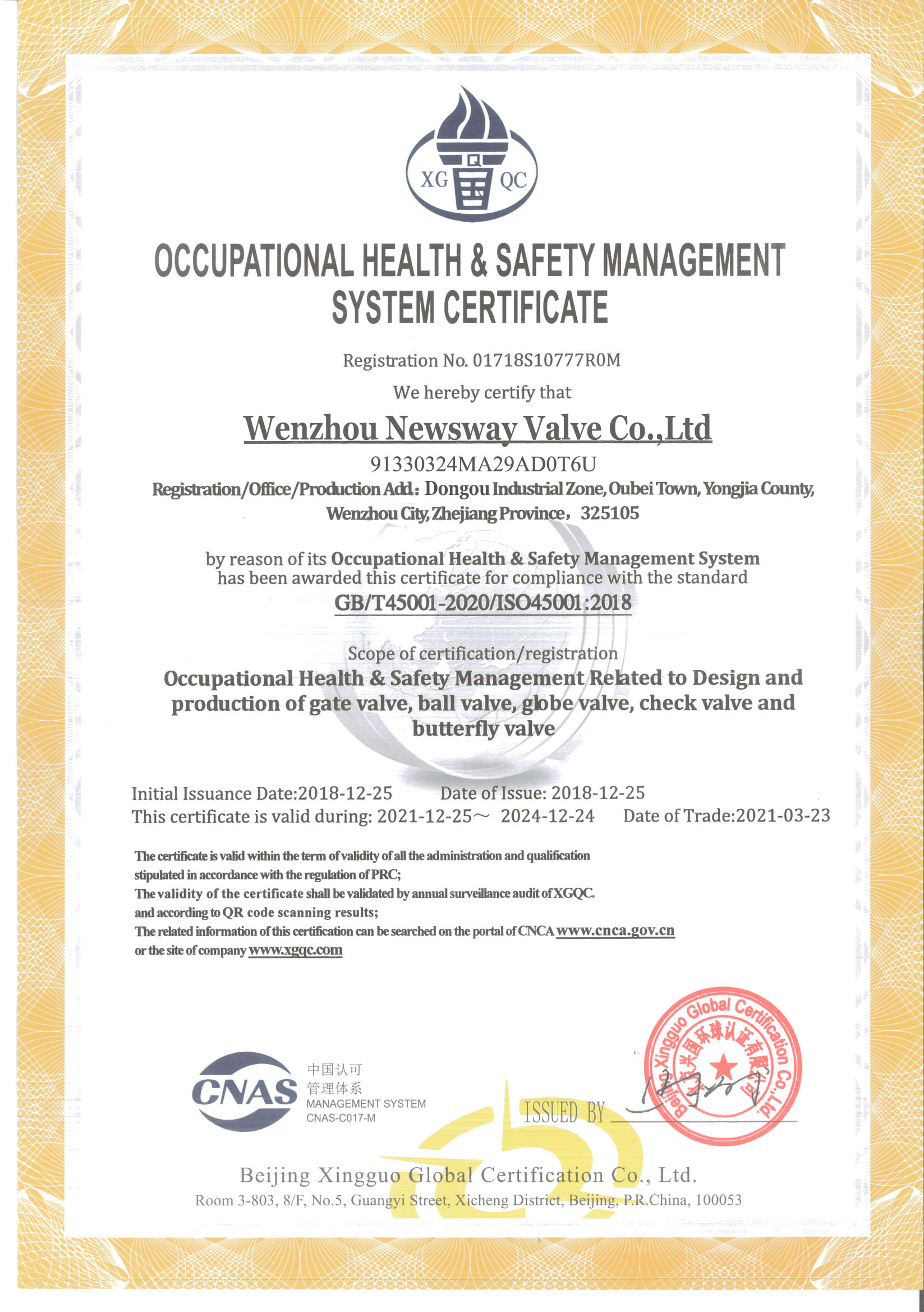

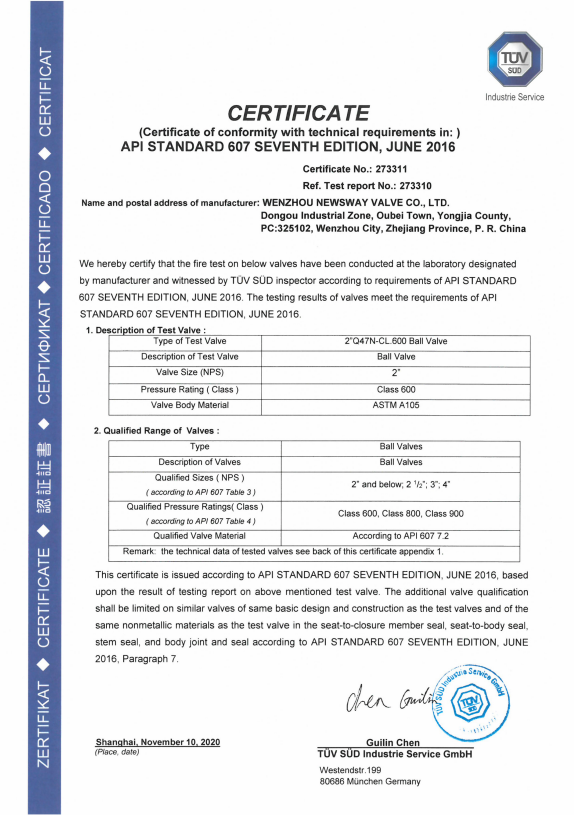

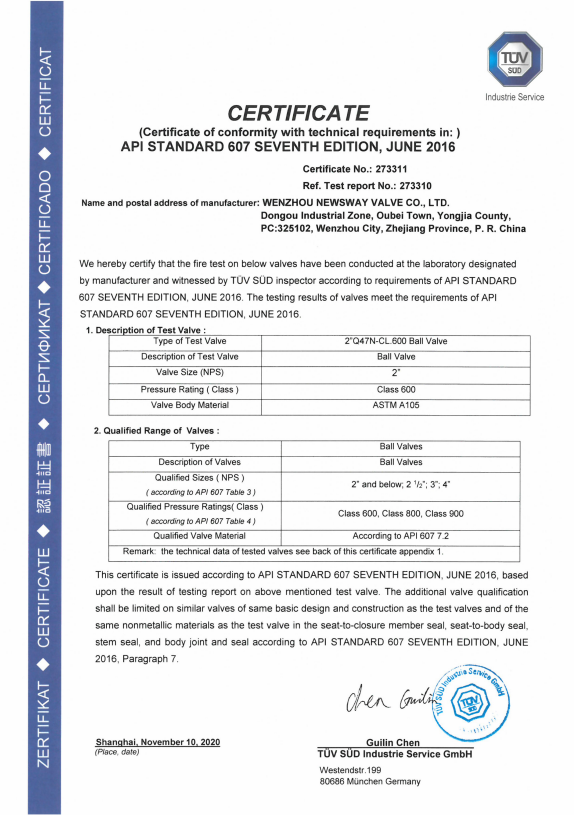

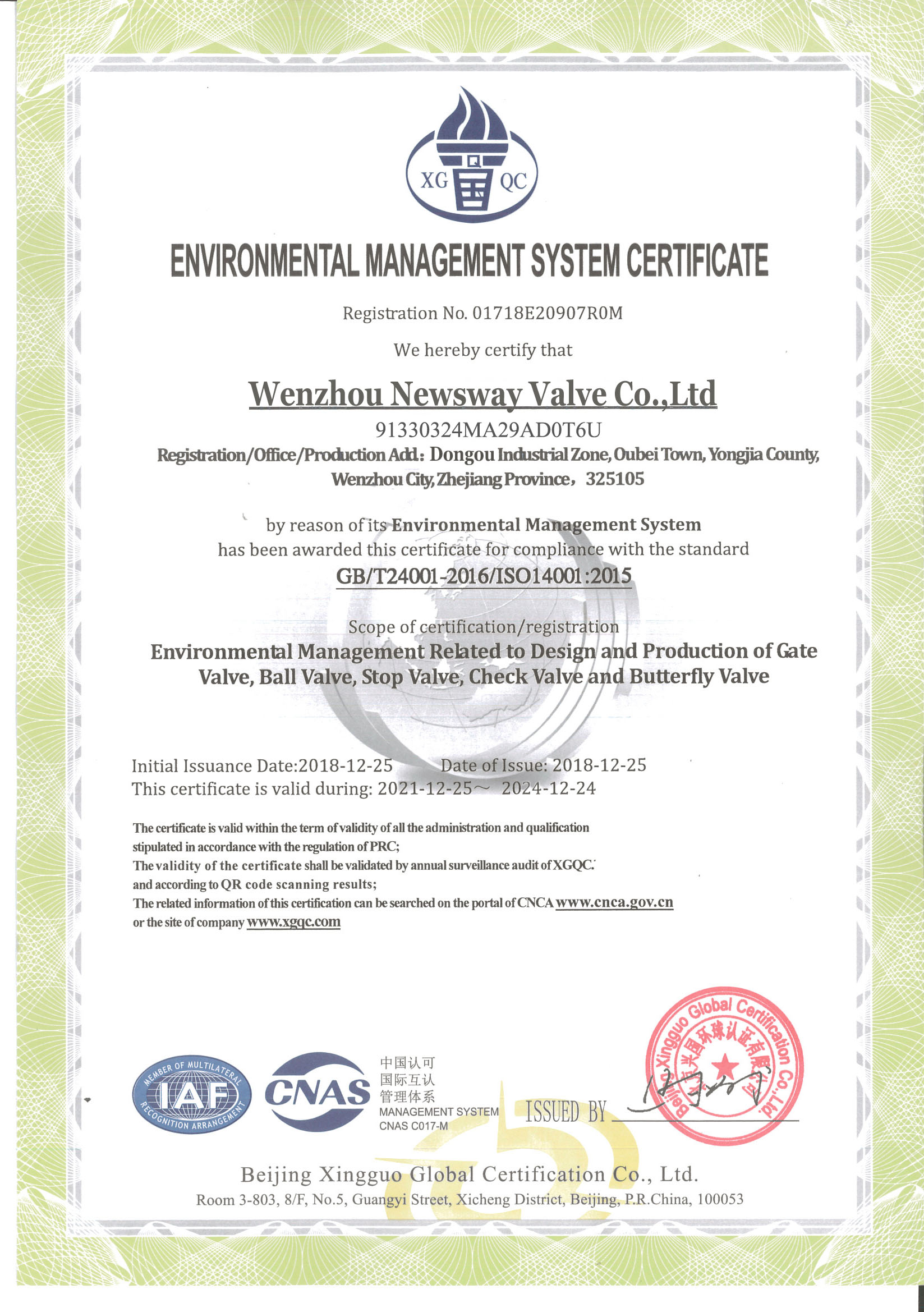

Authoritatively Certified

As our factory complies with ISO quality management requirements, NSW’s Forged Steel Gate Valve are made following ANSI/API, BS, DIN, JIS, GOST and GB standards. Over the years, we have earned numerous certifications to provide you with an effective guarantee of our products’ quality.

TUV-SIL3

TUV-API 607/6FA

TUV-SIL3

TUV-API 607/6FA

API-6D

API-600

Certificates of Materials, Products & Factory

API 607

PED-CE

ISO 9001

IS0 14001

ISO 45001

API 607-Ball Valve

Fugitive Emissions Certificates

Cryogenic Test