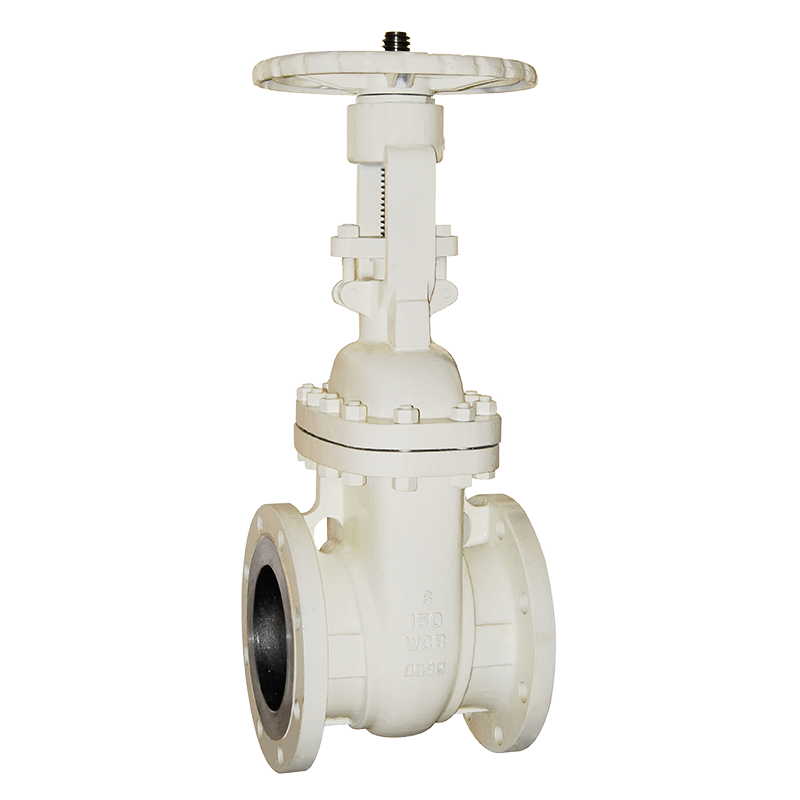

Top 10 Gate Valves Manufacturer In China

NSW VALVE is one of top 10 gate valves manufacturer in china with more than 20+ experience for gate valves producing and export. As a top gate valves factory, the carbon steel gate valve, stainless steel gate valve, flange gate valve, wafer gate valve, high pressure gate valves, cyogenic gate valves and special alloy gate valve produced by our company are popular all over the world. welcome to contact us for our gate valves catalogue in free.

How to choose a gate valve

NSW is a specialized gate valve production factory. We have our own gate valve body casting foundy, professional gate valve processing equipment and professional gate valve quality control department. We will provide you with the source gate valve factory price

Pressure sealed bonnet gate valve used to high pressure and high temperature piping adopts butt welded end connection method and is suitable for high pressure environments such as Class 900LB, 1500LB, 2500LB, etc. The valve body material is usually WC6, WC9, C5, C12, etc.

China, API 600, Gate Valve, Bolt Bonnet, Manufacture, Factory, Price, Flexible, Solid Wedge, Gate Valve, Bolt Bonnet, Flanged, RF, RTJ, trim 1, trim 8, trim 5, Metal, seat, full bore, Rising stem, Non Rising Stem, OS&Y, valves materials have carbon steel, stainless steel, A216 WCB, A351 CF3, CF8, CF3M, CF8M, A352 LCB, LCC, LC2, A995 4A. 5A, A105(N), F304(L), F316(L), F11, F22, F51, F347, F321, F51, Alloy 20, Monel, Inconel, Hastelloy, Aluminum Bronze and other special alloy. Pressure from Class 150LB, 300LB, 600LB, 900LB, 1500LB, 2500LB

NSW Gate Valve Manufacturer 6 inch gate valves price are very competitively. We have our own gate valve foundry. We have a large inventory of valves and valve castings for our 6 inch gate valves, 4 inch gate valves, and 2 inch gate valves and 8 inch gate valve, we can delivery gate valves in short delivery times.

How To Control Valve Quality Of Gate Valve

Key measures to control gate valve quality include material control, processing technology control and inspection standard control.

Gate Valve Material

The quality control of gate valves should start with the material. Generally speaking, gate valves are mainly used to control medium and low pressure water and oil and gas and other media, so the material selection should have strong toughness, corrosion resistance and high temperature resistance. In addition, attention should be paid to the uniformity and purity of the material to ensure the quality stability and reliability of the product.

Gate Valve Processing technology

The processing technology of the gate valve also has a great impact on its quality. During the processing, attention should be paid to the following aspects:

Positioning technology: It is necessary to accurately grasp the positioning and assembly of the gate valve, ensure the assembly accuracy and axis deviation, and avoid poor sealing caused by assembly errors.

Machining technology: The processing technology should have certain characteristics of eliminating internal stress, improving toughness and wear resistance.

Strict inspection: Strict inspection should be carried out in each link to ensure that each link meets the quality requirements.

Gate Valve Inspection Procedure

The inspection procedure of gate valves include installation dimensions, pressure test, valve sealing test and appearance inspection. During the manufacturing process, various standards need to be strictly followed to ensure the quality stability and reliability of the products. At the same time, they also need to be customized and processed according to customer requirements to meet their special usage needs.

How To Choose a Suitable Gate Valve Supplier

First of all, you should choose a gate valve supplier with good reputation and rich experience. When choosing a supplier, you should strictly review its qualifications, production equipment and process level. NSW will be your partner of China valve manufacture.

Strictly control the quality of raw materials

The materials used in gate valves directly affect their quality. You should choose high-quality raw material suppliers and conduct strict quality inspection and control on the raw materials.

Strengthen production process control

In the production of gate valves, process control should be strengthened, and operations should be strictly carried out in accordance with process regulations to ensure strict control of each link to prevent quality risks caused by improper operation.

Improve the quality inspection system

After the production of gate valves is completed, comprehensive and detailed quality inspections should be carried out. The inspection equipment should be advanced and accurate, and the inspection methods should be strictly operated in accordance with standards.

Strengthen after-sales service

The quality issues raised by customers should be responded to quickly, the quality issues that arise should be solved in a timely manner, and products and services should be actively improved to continuously improve customer satisfaction.

What Are The Classifications of Gate Valves

The classification of gate valves can be divided from multiple dimensions, mainly including the structure of the gate valve, the operation method of the gate valve, the connection method of the gate valve and the classification of the use of the gate valve.

Classification by gate valve structural characteristics |

|

| Rising Stem Gate Valve | The stem nut is above the valve body or valve cover. When opening and closing the gate, the stem nut is rotated to achieve the lifting and lowering of the stem. The advantage of this structure is that the threaded part of the stem is not corroded by the medium, which is convenient for lubrication and maintenance, and the opening and closing state is obvious. |

| Non-rising Stem Gate Valve | The stem nut is in the valve body and in direct contact with the medium. When opening and closing the gate, the stem is rotated to achieve the lifting and lowering of the stem. The advantage of this structure is that the stem height is small and the opening space is also small, but the threaded part of the stem is easily corroded by the medium and is not easy to lubricate. |

| Wedge Gate Valve | The gate and the valve seat sealing surface are at a certain angle (usually 3°, 5°, 8° or 10°, etc.), and the wedge gate is used to produce elastic deformation on the valve seat sealing surface to achieve a sealing effect. The advantage of this structure is good sealing performance, but the torque required for opening and closing is large. |

| Parallel Gate Valve |

The gate and the valve seat sealing surface are parallel to each other, and sealing is achieved by lifting and lowering the gate. The advantage of this structure is that the opening and closing torque is small, but the sealing performance is relatively poor. |

| Knife Gate Valve | Knife gate valve is a commonly used valve type. The gate of the knife gate valve cuts off the medium with a blade-shaped gate that can cut fiber materials. It has two sealing surfaces. The most commonly used mode is that the two sealing surfaces form a wedge shape. The wedge angle varies with the valve parameters and is usually 5°. |

Classification by gate valve actuator |

|

| Manual gate valve | The valve stem is driven to rise and fall by manually rotating the handle or handwheel to control the opening and closing of the gate. This driving method is simple and reliable, and is suitable for small and medium-sized gate valves. |

| Electric gate valve | The valve stem is driven to rise and fall by the motor to open and close the gate. This driving method has the advantages of high automation and convenient operation, and is suitable for large gate valves and those that require remote control. |

| Pneumatic gate valve | The valve stem is driven to rise and fall by a pneumatic device (such as a cylinder) to open and close the gate. This driving method has the advantages of rapid action and compact structure, and is suitable for occasions that require rapid opening and closing. |

| Hydraulic gate valve | The valve stem is driven to rise and fall by a hydraulic device (such as a hydraulic cylinder) to open and close the gate. This driving method has the advantages of large driving force and good stability, and is suitable for high-pressure and large-diameter gate valves. |

Gate Valves are Classified by Material

Stainless Steel Gate Valves

Stainless steel gate valves are divided into 304 stainless steel gate valves,316 stainless steel gate valves, 4A gate valves, 5A gate valves, 6A gate valves,

etc. Stainless steel gate valves have excellent corrosion resistance and strength,and are suitable for chemical, petroleum and other industries.

Forged Steel Gate Valve

Forged steel gate valves are suitable for high-pressure and high-temperature pipelines, and are usually used in oil pipelines. The operating temperature range

of forged steel gate valves is wide, from -29℃ to 425℃ or 500℃.

Cast Steel Gate Valves

Cast steel gate valves are suitable for high-pressure and high-temperature industrial environments, have good tensile strength and pressure resistance, and are often used in pipelines in the oil, smelting and other industries.

Carbon Steel Gate Valves

Carbon steel gate valves are suitable for oil, chemical, natural gas and other industries, and have good mechanical properties and cost-effectiveness. The valve body and valve cover of carbon steel gate valves are usually made of WCB, A105 or LF2 and other materials.

Cast Iron Gate Valve

Cast iron gate valves are widely used due to their low cost and are suitable for low pressure and low temperature occasions such as water supply, wastewater, and heating. Common cast iron gate valves include gray cast iron gate valves and ductile iron gate valves.

Bronze Alloy Gate Valve

Copper alloy gate valves have good machinability and strength and are suitable for seawater and gate valves in low pressure applications, such as bronze gate valve, aluminium bronze gate valve, C95800 gate valves, B62 gate valves, etc.

Alloy Steel Gate Valve

Alloy steel gate valves are suitable for higher temperature and high pressure application scenarios, usually using chromium molybdenum vanadium steel gate valves, duplex steel gate valves, super duplex steel gate valves, Hastelloy gate valves, titanium alloy gates and MONEL gate valves and other materials to provide higher strength and pressure resistance.

Ceramic Gate Valve

Ceramic gate valves are lined with ceramic materials, have excellent corrosion resistance and high temperature resistance, and are suitable for extremely corrosive media and high temperature and high pressure situations.

Plastic Gate Valve

Plastic gate valves are suitable for low-pressure, low-temperature corrosive media. Common plastic materials include PVC gate valves, UPVC gate valves, PP gate valves, etc.

Classification by Gate Valve Temperature

Normal Temperature Gate Valve

a gate valve suitable for medium temperatures within the normal temperature range.

High Temperature Gate Valve

a gate valve suitable for medium temperatures with high temperatures, usually using high temperature resistant materials and special structures to ensure the normal operation of the valve.

Cryogenic Gate Valve

a gate valve suitable for medium temperatures with low temperatures, usually using low temperature resistant materials and special structures to prevent the valve from brittle cracking or deformation at low temperatures.

Classification by Gate Valve Connection Method

Flange Gate Valve

connected to the pipeline through flange, with advantages such as firm connection and good sealing performance.

Threaded Gate Valve

connected to the pipeline through thread, with advantages such as easy installation and simple disassembly.

Welded Gate Valve

connected to the pipeline through welding, with advantages such as tight connection and not easy to leak.

What Working Conditions Are Gate Valves Suitable For

NSW VALVE is a source gate valve manufacturer with excellent gate valve design structure. The gate valve design standard complies with API 600, API 6D and other standards. The gate valve has light torque and good sealing performance.

Oil and natural gas pipelines. Flat gate valves with diversion holes are also convenient for cleaning pipelines.

Product oil pipelines and storage equipment.

Oil and natural gas wellhead equipment, that is, valves for Christmas trees.

Pipelines with suspended particles.

City gas pipelines.

Tap water projects.