Products

limit switch box-Valve Position Monitor -travel switch

LIMIT SWITCH BOX

VALVE POSITION MONITOR

VALVE TRAVEL SWITCH

The limit switch box is also called a Valve Position Monitor or a valve travel switch. It is actually an instrument that displays (reacts) the valve switch status. At close range, we can intuitively observe the current open/close state of the valve through the "OPEN"/"CLOSE" on the limit switch. During remote control, we can know the current open/close state of the valve through the open/close signal fed back by the limit switch displayed on the control screen.

NSW Limit Swith Box (Valve Position Return Device) models: Fl-2n, Fl-3n, Fl-4n, Fl-5n

|

|

FL 2N |

FL 3N |

The valve limit switch is an automatic control appliance that converts machine signals into electrical signals. It is used to control the position or stroke of moving parts and realize sequence control, positioning control and position state detection. It is a commonly used low-current master electrical appliance that plays a vital role in automatic control systems. The valve limit switch (Position Monitor) is a field instrument for valve position display and signal feedback in the automatic control system. It outputs the open or closed position of the valve as a switch quantity (contact) signal, which is indicated by the on-site indicator light or accepted by the program control or computer sampled to display the open and closed position of the valve, and execute the next program after confirmation. This switch is usually used in industrial control systems, which can accurately limit the position or stroke of mechanical movement and provide reliable limit protection.

|

|

FL 4N |

FL 5N |

There are various working principles and types of valve limit switches, including mechanical limit switches and proximity limit switches. Mechanical limit switches limit mechanical movement through physical contact. According to the different modes of action, they can be further divided into direct-acting, rolling, micro-motion and combined types. Proximity limit switches, also known as contactless travel switches, are non-contact trigger switches that trigger actions by detecting physical changes (such as eddy currents, magnetic field changes, capacitance changes, etc.) generated when an object approaches. These switches have the characteristics of non-contact triggering, fast action speed, stable signal without pulsation, reliable operation and long service life, so they have been widely used in industrial production.

|

|

FL 5S |

FL 9S |

Limit switch box features

l solid and flexible design

l die-cast aluminum alloy or stainless steel shell,all metal parts outside are made of stainless steel

l built in visual position indicator

l quick-set cam

l Spring loaded splined cam-----no adjustment required after

l dual or multiple cable entries;

l anti-loose bolt (FL-5)-the bolt attached to the upper cover will not fall off during removal and installation.

l easy installation;

l connecting shaft and mounting bracket according to NAMUR standard

Description

Display

- multiple types Of display windows are optional

- intensive polycarbonate;

- standard 90°display (optional 180°)

- eye standard color:open-yellow,close-red

Housing body

- aluminum alloys,stainless steel 316ss/316sl

- zigzag or thread binding surface (FL-5 Series)

- standard 2 electrical interfaces (up to 4 electrical interfaces,specifications NPT,M20,G,etc.)

- O-ring seal:fine rubber,epdm,fluorine rubber and silicone rubber

Stainless steel shaft

- stainless steel: Namur standard or customer custom

- anti shaft design(FL-5N)

- applicable environment:conventional-25°C~60 ℃,-40°C~60 ℃,optional specification:-55℃~80℃

- protection standard:IP66/IP67;optional;IP68

- explosion-proof grade:Exdb IIC T6 Gb、Ex ia IIC T6Ga、Ex tb IIC T80 Db

Anti-corrosion Treatment Of Explosion-proof Surface And Shell Surface

- anti-corrosion above WF2,neutral salt spray test tolerance for 1000 hours;

- treatment:DuPont resin+anodizing+anti-ultraviolet coating

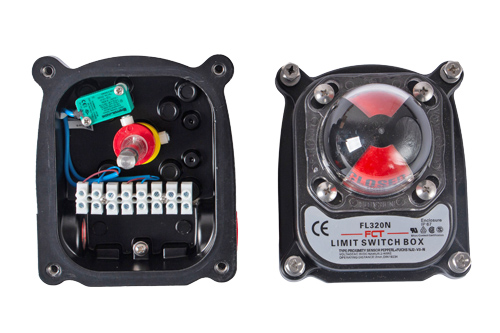

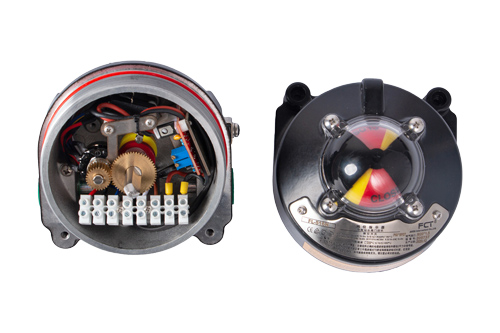

Schematic diagram of internal composition

- The unique gear meshing design can quickly and accurately adjust the sensing position of the sensor.The position of the switch can be easily set in the middle. The gears are dense and the upper and lower meshing design effectively avoids the deviation caused by vibration and effectively ensures the stability of the signal. High-precision gear+high-precision cam realizes micro-angle differentiation (deviation is less than +/-2%)

- The upper cover is tightly connected with the shaft to prevent water and pollutants from entering the cavity when the indicator is damaged,and to ensure normal operation for a certain period of time.Internal metal parts (including the spindle): stainless steel

- internal metal parts (including spindle): stainless steel;

- terminal block:standard 8-bit terminal block (option 12-bit);

- anti-static measures:internal ground terminal;

- sensor or micro switch:mechanical/inductive proximity/magnetic proximity

- internal corrosion protection:anodized/hardened

- internal wiring:circuit board (FL-5 series)or wiring harness

- options:solenoid valve/4-20mA feedback/HART protocol/bus protocol/wireless transmission

- Aluminum die-cast housing,compact structure,light weight,sturdy and durable.

- With double chromate treatment and polyester powder coating,the valve has high corrosion resistance.

- Cams loaded with spring,the limit position can be easily set

- without tools.

- Double seal indicator can prevent water inflow in case of dome failure.