Is the ball valve better: A comprehensive comparison with gate valves, butterfly valves and plug valves

When it comes to choosing the right valve for a specific application, the choices can be overwhelming. The most commonly used valves across a variety of industries include ball valves, gate valves, butterfly valves, and plug valves. Each type of valve has its own unique features, advantages, and disadvantages. In this article, we will explore the differences between these valves, focusing on the following questions: Is a ball valve better.

Understanding valve types

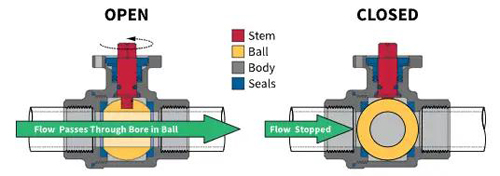

1. Ball valve

A ball valve is a quarter-turn valve that uses a spherical disc (ball) to control the flow of fluid. The ball has a hole in the center that allows fluid to pass when the valve is open. When the valve is closed, the ball rotates 90 degrees, blocking the flow of fluid. Ball valves are known for their durability, reliability, and ability to provide a tight seal.

Ball valve advantages:

– Quick Operation: Only a quarter turn is required to open or close the ball valve, making it ideal for applications requiring fast closing.

– Low Pressure Drop: When fully open, the ball valve offers minimal resistance to flow, resulting in a low pressure drop.

– Durability: The ball valve is made of strong materials that can withstand high pressure and temperature, suitable for a variety of applications.

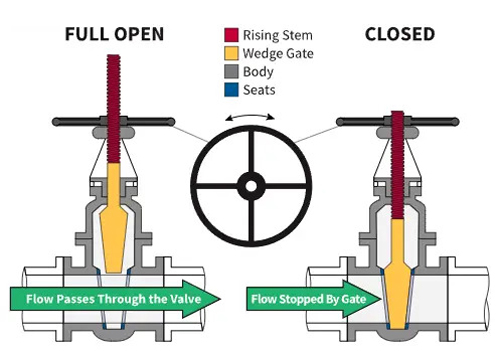

2. Gate valve

A gate valve is a linear motion valve that uses a gate (or wedge) to control the flow of fluid. The gate moves up and down to open or close the valve. Gate valves are typically used in applications where the valve is either fully open or fully closed, as they are not designed for throttling.

Advantages of gate valve:

– Minimum Flow Resistance: When fully open, a gate valve provides a straight-through flow path, creating minimal resistance.

– Suitable for high pressure applications: Gate valves can withstand high pressure and are commonly used in oil and gas applications.

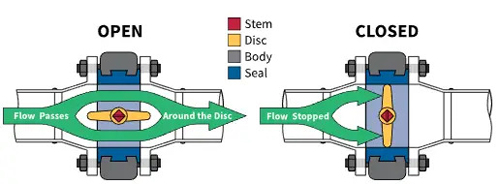

3. Butterfly valve

A butterfly valve is a quarter-turn valve that uses a rotating disc to control the flow of fluid. The disc is mounted on a shaft and can be rotated to open or close the valve. Butterfly valves are commonly used in large-scale applications due to their lightweight design and compact size.

Advantages of butterfly valve:

– Space-saving design: Butterfly valves are more compact than other types of valves, making them ideal for applications where space is limited.

– Cost-effective: Generally speaking, butterfly valves are less expensive than ball valves and gate valves, making them a cost-effective choice in many applications.

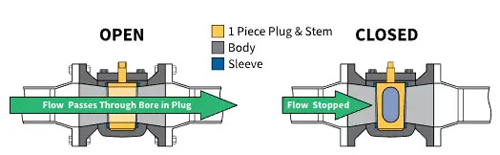

4. Plug valve

A plug valve is similar to a ball valve, but uses a cylindrical or tapered plug to control flow. The plug has a hole that aligns with the inlet and outlet when the valve is open. Plug valves are known for their simplicity and ease of use.

Advantages of plug valve:

– Simple design: Plug valves have fewer moving parts, making them easy to operate and maintain.

– Good Sealing Ability: When closed, the stopcock provides a tight seal to prevent leakage.

Ball valve Vs. gate valve

When comparing ball valves and gate valves, there are several factors to consider:

- Operation Speed: Ball valves operate faster than gate valves, making them better suited for applications that require fast closing.

– Flow Control: While both valves offer minimal resistance to flow when fully open, ball valves offer better control in throttling applications.

– Sealing performance: Ball valves generally have better sealing than gate valves, thus reducing the risk of leakage.

In summary, ball valves are generally considered superior to gate valves in applications that require fast operation and reliable sealing.

Ball valve Vs. butterfly valve

A comparison of ball valves and butterfly valves highlights the following differences:

- Size and weight: Butterfly valves are generally lighter and more compact than ball valves, making them easier to install in tight spaces.

– Cost: Butterfly valves are generally more cost-effective than ball valves, making them a popular choice for large-scale applications.

– Flow Control: Compared with butterfly valves, ball valves have better flow control and sealing capabilities, especially in high-pressure applications.

While butterfly valves may be better suited for certain applications, ball valves are preferred for their superior sealing and flow control.

Ball valve Vs. plug valve

When comparing ball valves and plug valves, consider the following:

- Design Complexity: The design of a ball valve is more complex than a plug valve, which makes it more expensive to manufacture.

– Sealing Performance: Both valves have good sealing capabilities, but ball valves generally have better performance in high-pressure applications.

– Operation: Ball valves are quicker to operate compared to plug valves, which may require more effort to turn the plug.

In many cases, ball valves are preferred over plug valves due to their superior performance and ease of use.

Is a ball valve better

Whether a ball valve is better than other types of valves depends on the specific application and requirements. Here are some key considerations:

1. Application Requirements

- Pressure and Temperature: Ball valves are suitable for high pressure and high temperature applications, making them ideal for industries such as oil and gas, chemical processing, and power generation.

– Flow Control Needs: If precise flow control is required, ball valves are often the first choice as they provide a tight seal and minimal flow resistance.

2. Installation and Maintenance

- Easy to Install: Ball valves are generally easy to install and require minimal maintenance, making them a practical choice for many applications.

– Durability: The rugged construction of the ball valve ensures a long service life, reducing the need for frequent replacement.

3. Cost Considerations

- Initial Investment: Although ball valves have a higher initial cost compared to other types of valves, their durability and low maintenance requirements can save costs in the long run.

In conclusion

In summary, ball valves offer many advantages over gate, butterfly, and plug valves, especially in applications that require fast operation, reliable sealing, and high-pressure capabilities. While each valve type has its own unique features and benefits, ball valves are generally considered the best choice for many industrial applications. When selecting a valve, it is important to consider the specific requirements of the application, including pressure, temperature, flow control needs, and budget constraints. Ultimately, the correct valve selection will depend on the unique needs of the system in which the valve will be used.

As a leading manufacturer in China, we understand the importance of choosing the right valve for your needs. We offer a range of high-quality ball valves, gate valves, butterfly valves and plug valves designed to meet the various needs of different industries. Whether you need valves for high-pressure applications or cost-effective solutions for large projects, we have the expertise and products to help you make the best choice.

Post time: Mar-19-2025