When it comes to industrial fluid control systems, ball valves are among the most reliable and versatile components. Their ability to handle high-pressure and high-temperature applications makes them indispensable across industries. This article explores the classification of big size ball valves, their types, and key considerations when sourcing from a trusted ball valve manufacturer or supplier in China.

What is a Ball Valve

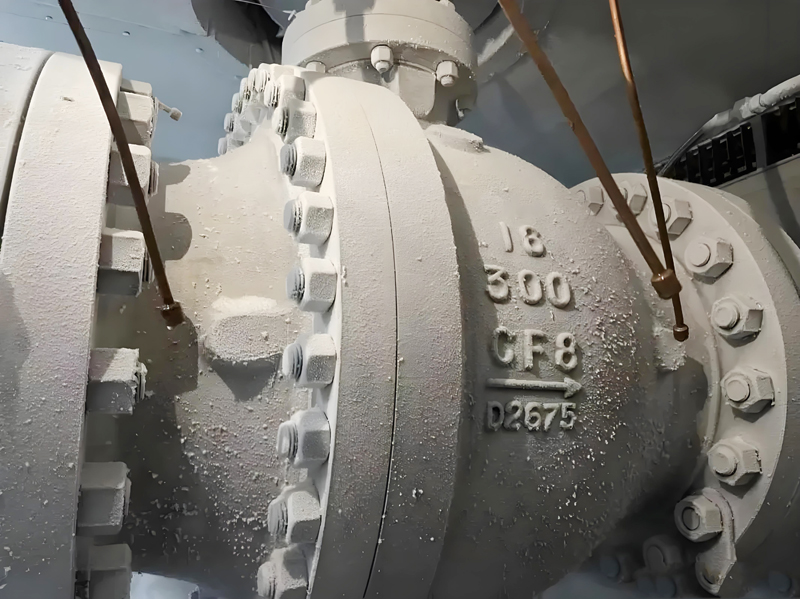

A ball valve is a quarter-turn valve that uses a hollow, perforated, and pivoting ball to control fluid flow. When the valve is open, the ball’s hole aligns with the pipeline, allowing fluid to pass. When closed, the ball rotates 90 degrees to block the flow. Its simple design ensures durability, minimal leakage, and ease of operation.

Big size ball valves, typically defined as those with a diameter of 40 inches (DN1000) or larger, are engineered for heavy-duty applications in oil and gas, water treatment, chemical processing, and power generation.

Valve of the Ball: Key Components

Understanding the anatomy of a ball valve is critical to selecting the right type for your needs:

1. Body: Houses internal components; common materials include stainless steel, cast iron, and carbon steel.

2. Ball: The rotating sphere with a bore that regulates flow.

3. Seats: Create a seal between the ball and body.

4. Stem: Connects the actuator to the ball for rotation.

5. Actuator: Manual lever, gear, or automated system (electric/pneumatic).

For big size ball valves, robust construction and reinforced sealing mechanisms are essential to withstand extreme pressures and flow rates.

Ball Valve Types: Classification Based on Design

Ball valves are classified into several types based on their design and functionality:

Floating Ball Valve

- The ball is suspended by the seats, ideal for smaller sizes.

- Cost-effective but less suited for big size ball valves due to higher torque requirements.

Trunnion Mounted Ball Valve

- The ball is anchored by a trunnion (pivot), reducing operational torque.

- Preferred for big size ball valves in high-pressure oil and gas pipelines.

Full Bore vs. Reduced Bore

- Full bore: The ball’s diameter matches the pipeline, minimizing pressure drop.

- Reduced bore: Smaller ball opening, suitable for space-constrained systems.

Multi-Port Ball Valve

- Features multiple ports for flow diversion, used in complex distribution systems.

Cavity-Filled Ball Valve

- Designed to prevent fluid entrapment in the ball cavity, critical for sanitary or corrosive applications.

Why Choose a Big Size Ball Valve

Big size ball valves are essential for:

- High-flow systems: Efficiently manage large volumes of liquids or gases.

- Durability: Built to handle abrasive or corrosive media.

- Precision control: Ensure reliable shut-off in critical applications.

Selecting a Reliable Big Size Ball Valve Manufacturer

When sourcing big size ball valves, partnering with a reputable ball valve factory or supplier in China offers advantages like competitive price, customization, and adherence to international standards (API, ANSI, ISO). Key factors to consider:

1. Material Quality: Ensure valves are crafted from corrosion-resistant alloys.

2. Certifications: Look for ISO 9001, API 6D, or CE marks.

3. Customization: Opt for manufacturers offering tailored solutions for unique operational needs.

4. After-Sales Support: Warranty, technical assistance, and spare parts availability.

China remains a global hub for ball valve manufacturing, with suppliers combining advanced technology and cost efficiency.

Conclusion

From floating ball valves to heavy-duty trunnion mounted designs, understanding the classification of big size ball valves ensures optimal selection for industrial applications. Whether you prioritize price, durability, or precision, partnering with a trusted China ball valve supplier guarantees access to high-performance solutions.

For industries requiring reliable flow control, investing in quality big size ball valves from a certified manufacturer is a strategic decision that enhances operational efficiency and safety.

Post time: Feb-20-2025