When it comes to critical fluid control systems, forged steel gate valves stand out as a cornerstone of reliability and durability. Designed to withstand extreme pressures and temperatures, these valves are indispensable in industries such as oil and gas, petrochemicals, and power generation. Alongside forged steel globe valves, forged steel check valves, and forged steel ball valves, they form a family of high-performance components engineered for precision and longevity.

Why Choose Forged Steel Valves

Forged steel valves are manufactured using a specialized process that compresses and shapes steel under high pressure. This method enhances the material’s structural integrity, making the valves resistant to cracking, corrosion, and wear. Key advantages include:

- Superior strength: Ideal for high-pressure environments (e.g., Class 800LB, Class 2500LB, and Class 150LB systems).

- Leak-proof performance: Tight sealing capabilities ensure zero fluid loss.

- Versatility: Compatible with steam, oil, gas, and corrosive media.

Exploring Valve Types and Their Applications

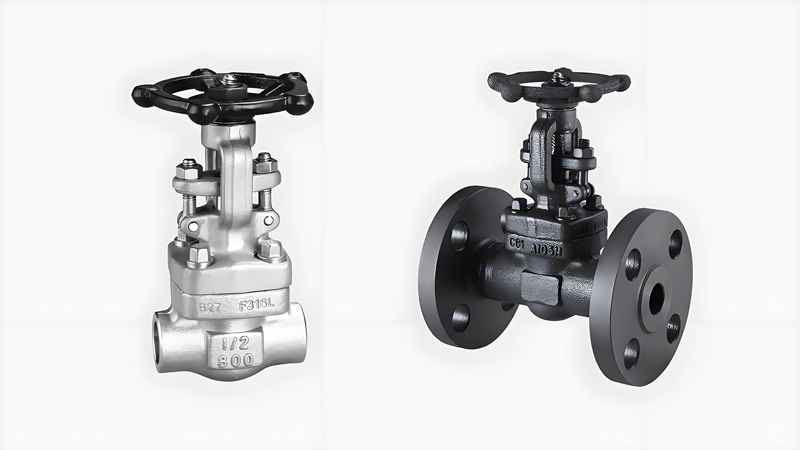

1. Forged Steel Gate Valve

Gate valves are designed for on/off control in pipelines. Their wedge-shaped gate provides a tight seal, minimizing pressure drop when fully open. Commonly used in Class 150, Class 800 to Class 2500 systems, they excel in high-temperature oil and gas pipelines.

2. Forged Steel Globe Valve

Globe valves regulate flow with a movable disc and stationary ring seat. Their precise throttling capability makes them ideal for systems requiring frequent adjustments, such as cooling water or chemical processing lines.

3. Forged Steel Check Valve

These valves prevent backflow, protecting pumps and compressors. Their swing or lift design ensures automatic closure when flow reverses, often specified in Class 800 steam systems.

4. Forged Steel Ball Valve

Ball valves offer quick shut-off with a quarter-turn mechanism. Their low torque and full-bore design suit high-flow applications, including LNG and refinery pipelines.

Pressure Classifications: Matching Class 150, 2500 and 800 Gate Valve to System Demands

- Class 150: Low-pressure systems (e.g., water distribution).

- Class 800: Medium-pressure industrial processes (e.g., steam networks).

- Class 2500: High-pressure applications (e.g., offshore drilling).

Selecting the correct pressure class ensures safety and compliance with industry standards like API 602, ASME B16.34.

Key Industries Served

Forged steel valves are critical in:

- Oil & Gas: Wellheads, pipelines, and refineries.

- Power Plants: Boiler feed systems and turbine bypass.

- Chemical Processing: Handling aggressive fluids.

Conclusion

Whether you need a forged steel gate valve for isolation, a forged steel globe valve for flow control, or a **forged steel check valve** for backflow prevention, choosing the right pressure class (150LB, 800LB, or 2500LB) is essential. These valves combine rugged construction with precision engineering, ensuring optimal performance in the most demanding environments.

For long-term reliability and compliance, partner with trusted manufacturers who specialize in forged steel valve solutions. Explore their catalogs to find the perfect fit for your industrial needs.

Post time: Feb-27-2025