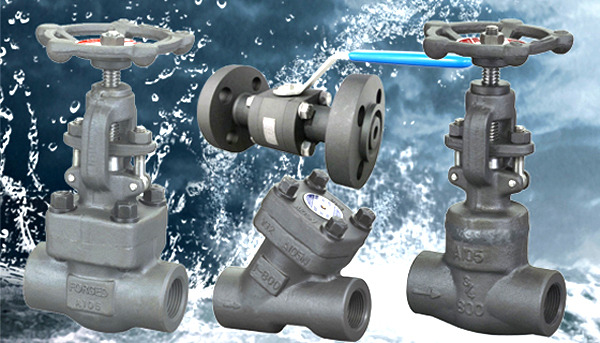

Forged Steel Valves are a common type of industry valves, and their name comes from the forging process of their key component, the valve body. Forged steel valves can be divided into Forged Steel Ball Valves, Forged Steel Gate Valves, Forged Steel Globe Valves, Forged Steel Check Valves, etc., and can be divided into ASTM A105 forging, A182, F304, F316, F316L, F22, F91, and F92 materials.

The top ten forged steel valve brands in the world are as follows:

1. NICO, USA

2. NOOK, Germany

3. NOTON, USA

4. BON, USA

5. KSB, USA

6. NSW, China

7. PAUL, UK

8. GAYLE, Germany

9. Thomas, Germany

10. Bonney, India

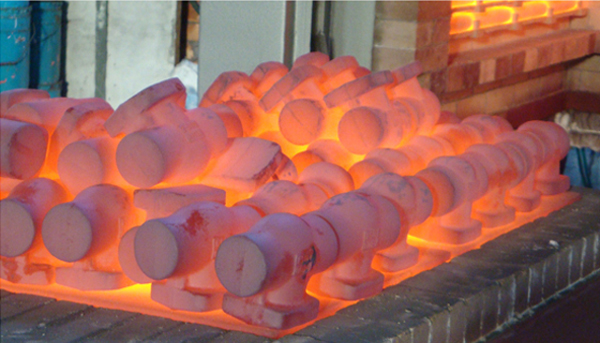

The manufacturing principle of forged steel valves is relatively simple. It mainly heats the raw materials at high temperature, and then forges, cuts, grinds and other processes to make valve bodies and valve trims. Compared with other valves, forged steel valves have higher pressure resistance and longer service life.

The characteristics of forged steel valves are mainly the following aspects:

Good sealing performance: The sealing surface between the valve trim and the valve seat of the forged steel valve is processed by high-precision grinding, which can achieve precise sealing effect.

Good pressure resistance: Since the ball and valve seat of the forged steel valve are processed by high-temperature forging, they have high strength and pressure resistance and can remain stable under high pressure.

Low fluid resistance: The flow channel of the forged steel valve is unobstructed, which can reduce fluid resistance and reduce fluid energy consumption.

Long service life: The components of the forged steel valve are processed by high-temperature forging, and the material quality is stable, which can ensure its long-term performance.

Easy maintenance: The switch operation of the forged steel valve is simple, and it can be opened and closed quickly, which is convenient for maintenance and maintenance.

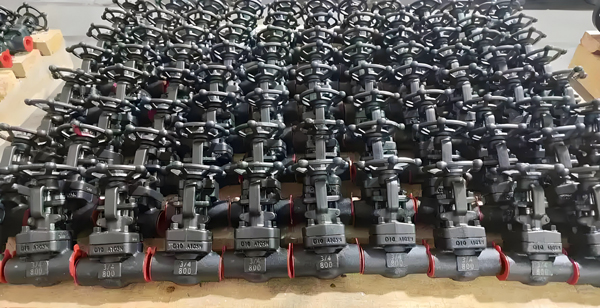

There are many specifications and models of forged steel ball valves. Generally, 1/2 Inch (DN15) – 4 Inch (DN100) models are commonly used, among which 1/2 inch forged steel valves and 2 inch forged steel valves are the most commonly used. For different usage occasions and needs, you can choose the appropriate model and specification according to the actual situation.

For the use and maintenance of forged steel valves, the following points should generally be noted:

When installing and using forged steel valves, it is necessary to ensure that the position and height of the valve meet the actual use requirements, and ensure that the installation is firm and reliable to prevent leakage or damage.

When opening and closing forged steel valves, it is necessary to operate slowly to avoid too fast or too violent operation that may cause damage to components or affect the life of the valve.

For forged steel valves that are not used for a long time, it is necessary to regularly check their sealing performance and usage status, and perform maintenance and care in time to maintain good working conditions.

When purchasing forged steel valves, it is necessary to choose regular brands and manufacturers, and pay attention to checking their quality assurance and instructions for use to ensure that you purchase high-quality valve products.

In short, as a common type of valve, forged steel valves have a wide range of applications and use value. Understanding its manufacturing principles, standards, characteristics, types, models, specifications, and precautions for use will help to better apply and maintain forged steel valves and achieve their long-term stable working performance and life.

Post time: Mar-11-2025