Complete Industrial Guide to Ball Valves (Types, Selection & FAQs)

Introduction

What is a Ball Valve? A Ball Valve is a quarter-turn shut-off valve that uses a hollow, perforated, and pivoting ball to control the flow of liquids or gases. Due to its simple structure, tight sealing performance, and fast operation, a Ball Valve has become one of the most widely used valves in industrial, commercial, and residential piping systems.

From oil and gas pipelines to water treatment facilities and chemical processing plants, understanding what a ball valve is and how to select the right one is critical for system safety, efficiency, and long-term reliability.

—

How Does a Ball Valve Work

A Ball Valve operates through a 90-degree rotation of the valve handle or actuator:

* When the ball’s bore aligns with the pipeline, fluid flows freely.

* When rotated 90°, the solid part of the ball blocks the flow completely.

This quarter-turn mechanism allows a Ball Valve to provide instant shut-off with minimal effort and reduced wear compared to multi-turn valves.

—

Main Components of a Ball Valve

To fully understand **what is a Ball Valve**, it helps to know its key components:

* Valve Body – Houses all internal components and connects to the pipeline

* Ball – A spherical disc with a bore that controls flow

* Seats – Create a tight seal around the ball (PTFE, metal, or composite)

* Stem – Connects the ball to the handle or actuator

* Actuator or Handle – Enables manual or automated operation

Each component contributes to the durability and sealing reliability of a Ball Valve.

—

Common Types of Ball Valves

Floating Ball Valve

In a floating Ball Valve, the ball is held in place by the valve seats and allowed to move slightly under pressure to achieve tight sealing.

Best for:

* Medium pressure systems

* Water, gas, and general industrial applications

—

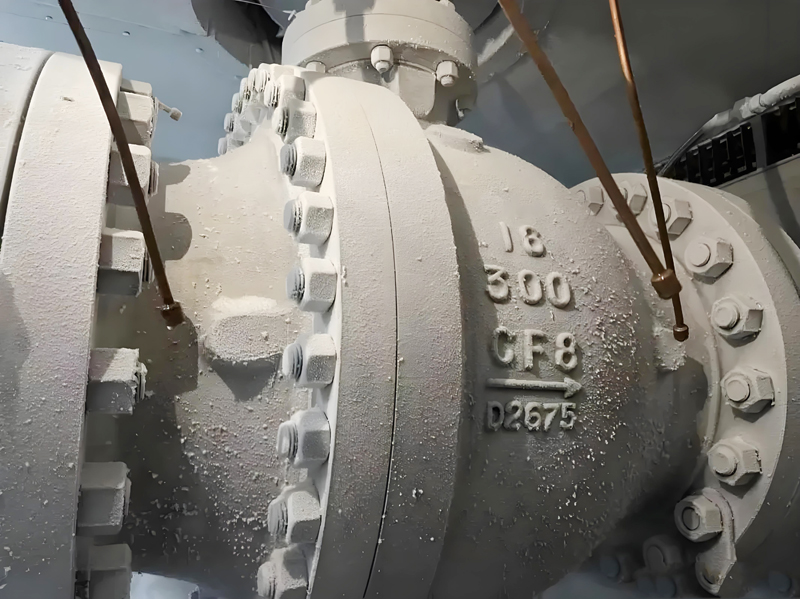

Trunnion Mounted Ball Valve

A trunnion Ball Valve uses mechanical anchors to support the ball, reducing torque and seat wear.

Best for:

* High-pressure pipelines

* Large-diameter systems

* Oil and gas transmission

—

Full Port vs Reduced Port Ball Valve

| Feature | Full Port Ball Valve | Reduced Port Ball Valve |

| —————— | ——————– | ———————– |

| Flow Area | Same as pipe | Smaller than pipe |

| Pressure Drop | Minimal | Slight |

| Pigging Capability | Yes | No |

| Cost | Higher | Lower |

Choosing between them depends on flow efficiency requirements and budget.

—

V-Port Ball Valve

A V-Port Ball Valve features a V-shaped bore, allowing more accurate flow regulation.

Best for:

* Flow control applications

* Chemical processing

* Automation systems

—

Ball Valve vs Other Valve Types

Ball Valve vs Gate Valve

* Ball Valve: Quick operation, excellent sealing, compact design

* Gate Valve: Slower operation, suitable for infrequent use

Ball Valve vs Globe Valve

* Ball Valve: Lower pressure loss, ideal for on/off control

* Globe Valve: Better throttling but higher pressure drop

In most industrial shut-off applications, a Ball Valve is the preferred solution.

—

How to Choose the Right Ball Valve

When selecting a Ball Valve, consider the following:

1. Media Type – Water, gas, oil, steam, or corrosive chemicals

2. Pressure & Temperature Rating – Must meet system requirements

3. Valve Size – Match pipe diameter for optimal performance

4. End Connection – Flanged, threaded, or welded

5. Operation Mode – Manual, pneumatic, or electric

Correct selection ensures long service life and operational safety.

—

Applications of Ball Valves

Ball Valves are commonly used in:

* Oil & Gas pipelines

* Petrochemical and chemical plants

* Water treatment and desalination

* HVAC and power generation

* Industrial manufacturing systems

Their versatility explains why what is a Ball Valve remains a frequently searched technical topic.

—

Frequently Asked Questions (FAQ)

What is a Ball Valve used for?

A Ball Valve is mainly used for quick and reliable on/off flow control in piping systems.

Can a Ball Valve regulate flow?

Standard Ball Valves are designed for shut-off. For flow control, a V-Port Ball Valve is recommended.

How long does a Ball Valve last?

With proper material selection and maintenance, a Ball Valve can last over 15–20 years.

Is a Ball Valve better than a gate valve?

For fast operation, tight sealing, and minimal maintenance, a Ball Valve is generally superior.

—

Conclusion

So, what is a Ball Valve? It is a highly efficient, durable, and versatile valve solution for modern flow control systems. Whether used in demanding industrial environments or everyday plumbing, a Ball Valve delivers reliable performance, long service life, and excellent sealing.

Understanding the types, applications, and selection criteria ensures you choose the right Ball Valve for your system needs.

Post time: Jan-23-2025