Understanding Bellow Seal Globe Valves

A bellow seal globe valve is a specialized shut-off valve designed to eliminate stem leakage in critical applications. Unlike traditional packed globe valves, it uses a metallic bellows assembly welded to both the stem and valve body, creating a hermetic seal. This design is essential for handling toxic, corrosive, or high-purity media where fugitive emissions are unacceptable.

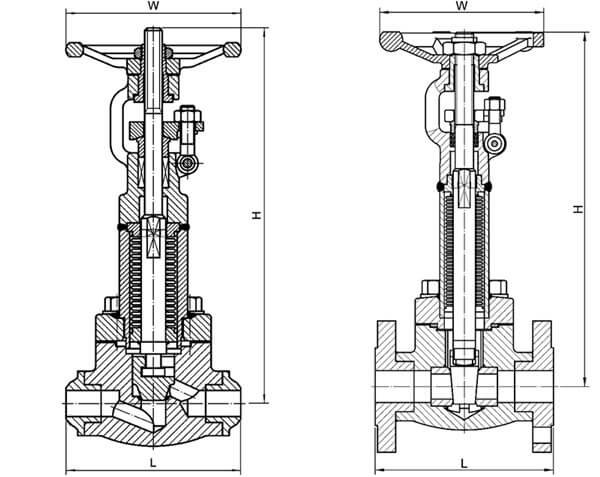

Key Components of Bellow Seal Globe Valves

1. Bellows Assembly

- Material: Stainless steel (SS316/316L), Inconel 625, or Hastelloy C276

- Design: Multi-ply convolutions (8-12 layers) for 10,000+ cycle durability

- Function: Compresses/extends during valve operation while maintaining seal integrity

2. Valve Body

- Pressure Rating: Class 150 to Class 2500 (ANSI/ASME B16.34)

- End Connections: Flanged (RF/RTJ), socket weld, or buttweld

- Temp Range: -196°C to 550°C (cryogenic to high-heat)

3. Stem & Disc

- Integral forged stem-disc assembly for alignment

- Surface hardening (Stellite 6 coating) for abrasion resistance

4. Secondary Seal (Backup)

- Graphite packing rings below bellows as fail-safe

How Does a Bellow Seal Globe Valve Work

Step 1: Opening the Valve

When the handwheel is rotated counterclockwise:

- The stem rises, lifting the disc from the seat

- Bellows compress axially, maintaining seal integrity

Step 2: Closing the Valve

Clockwise rotation:

- Stem forces disc against seat, stopping flow

- Bellows extend to original length

Step 3: Leakage Prevention

Double sealing action:

- Primary seal: Bellows block stem leakage path

- Secondary seal: Graphite packing (API 622 compliant)

Advantages Over Standard Globe Valves

| Feature | Bellow Seal Globe Valve | Packed Globe Valve |

|---|---|---|

| Stem Leakage | Zero fugitive emissions (ISO 15848-1 TA-Luft) | Up to 500 ppm leakage |

| Maintenance | No packing replacement needed | Annual packing maintenance |

| Applications | Hazardous, high-purity, vacuum systems | General water/steam services |

Industrial Applications

1. Chemical Processing

- Chlor-alkali plants (chlorine gas containment)

- Pharmaceutical API production

2. Oil & Gas

- HF alkylation units

- LNG cryogenic transfer (-162°C)

3. Power Generation

- Boiler feedwater isolation

- Steam turbine bypass systems

Selection Criteria

1. Bellows Type

- Forged Bellows: High-pressure (ASME Class 1500+)

- Welded Bellows: Corrosive media (electropolished finish)

2. Flow Characteristics

- Equal percentage vs. linear flow for control applications

3. Certifications

- NACE MR0175 for sour service

- PED 2014/68/EU for European markets

Top China Bellow Valve Manufacturers

Chinese manufacturers like NSW Valve Manufacturer offer:

- API 602/BS 1873 compliant designs

- 30% cost savings vs. European brands

- Custom bellows testing (helium leak detection)

Maintenance Best Practices

- Annual bellows inspection for fatigue cracks

- Stem lubrication with high-temperature grease

- Avoid over-torquing (max 50 Nm for DN50 valves)

Post time: Apr-10-2025