In the world of fluid dynamics and piping systems, check valves play a vital role in ensuring the efficient and safe flow of liquids and gases. As an essential component in a variety of industrial applications, understanding what a check valve is, its types and manufacturers can help engineers and procurement experts make informed decisions. This article will delve into the complexity of check valves, focusing on its types, functions and leading check valve manufacturers, especially in China.

Understanding Check Valves

A check valve, also known as a one-way valve, is a mechanical device that allows fluid to flow in one direction while preventing backflow. This is essential in many applications, such as water supply systems, sewage treatment, and various industrial processes. The primary function of a check valve is to protect equipment and maintain system integrity by preventing reverse flow, which could result in contamination, equipment damage, or system failure.

Working Principle of Check Valve

The working principle of a check valve is to use the pressure difference between upstream and downstream. When the pressure on the inlet side exceeds the pressure on the outlet side, the valve will open and allow the fluid to flow through. Conversely, if the pressure on the outlet side becomes greater, the valve will close and prevent backflow. This simple but effective mechanism makes the check valve indispensable in many systems.

Types of Check Valves

There are many types of check valves, each designed for specific applications and flow conditions. The most common types include:

1. Swing Check Valve

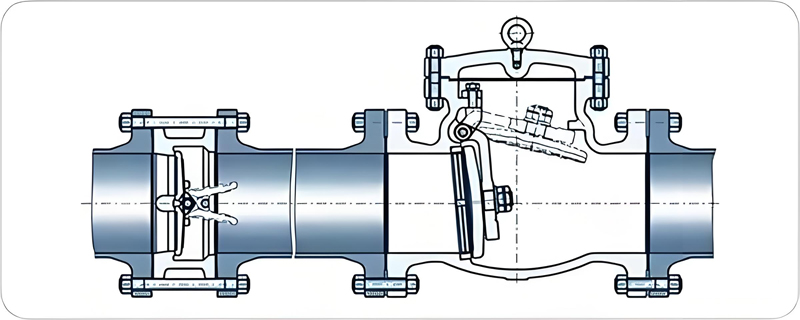

The swing check valve is one of the most widely used types. It features a disc that swings on a hinge, allowing fluid to flow in one direction while closing if backflow occurs. Swing check valves are ideal for low to medium flow applications and are commonly used in water systems, HVAC systems, and various industrial processes.

2. Dual Plate Check Valve

The double disc check valve consists of two plates that pivot on a common axis. This design allows for a more compact and lightweight valve compared to a conventional swing check valve. Double disc check valves are particularly effective in high flow applications and are commonly used in pipelines, water treatment plants, and the oil and gas industry.

3. Stainless Steel Check Valve

Stainless steel check valves are designed for applications that require corrosion resistance and durability. These valves are commonly used in chemical processing, food and beverage industries, and marine applications. Stainless steel construction ensures long service life and high reliability, making it the preferred choice of many engineers.

The Importance of Choosing the Right Check Valve Manufacturer

Selecting the right check valve manufacturer is critical to ensuring the quality and reliability of the valves used in your system. A reputable check valve manufacturer will provide products that meet industry standards and specifications, ensuring optimal performance and safety.

Why choose a Chinese check valve manufacturer?

China has become a major center for manufacturing a variety of industrial components, including check valves. The country has a wide range of check valve suppliers, offering everything from swing check valves to double plate check valves and stainless steel check valves. Here are some of the benefits of choosing a Chinese check valve manufacturer:

1. Cost-effective: Chinese manufacturers usually offer competitive prices because production costs are lower. This can result in significant cost savings for companies looking to purchase check valves in bulk.

2. Diverse product range: Chinese check valve suppliers usually offer a wide variety of products, allowing customers to find a specific type of check valve that meets their needs.

3. Quality Assurance: Many Chinese manufacturers adhere to international quality standards to ensure their products are reliable and durable. Certifications such as ISO 9001 can demonstrate a manufacturer’s commitment to quality.

4. Innovation and Technology: Chinese manufacturers are increasing their investment in advanced manufacturing technologies and processes to improve product design and performance.

5. Global Presence: Many Chinese check valve suppliers have established global operations, making their products and services more accessible to international customers.

Key Considerations When Purchasing Check Valves

When sourcing check valves from manufacturers, especially in China, there are several key considerations to keep in mind:

1. Quality Standards

Ensure that the manufacturer adheres to relevant quality standards and certifications. This includes ISO certification, as well as compliance with industry-specific standards such as API, ASME or ASTM.

2. Check Valve Product Range

Evaluate the manufacturer’s product range to ensure they offer the specific type of check valve you require, whether it is a swing check valve, double disc check valve or stainless steel check valve.

3. Customization options

Certain applications may require a custom check valve. Check to see if the manufacturer offers custom options to meet your specific needs.

4. Lead Time and Delivery

Consider the manufacturer’s lead time and ability to deliver. Timely delivery is critical to keeping your project on schedule and avoiding costly delays.

5. After-sales support

Evaluate the level of post-sales support provided by the manufacturer. This can include warranty information, technical support, and installation and maintenance assistance.

in conclusion

In summary, check valves are essential components in a variety of fluid systems, providing a reliable method of preventing backflow and ensuring system integrity. Understanding the different types of check valves, such as swing check valves, double plate check valves, and stainless steel check valves, is essential to selecting the right product for your application.

When sourcing check valves, especially from a Chinese manufacturer, it is important to consider factors such as quality standards, product range, customization options, delivery times, and after-sales support. By making an informed decision and working with a reputable check valve manufacturer, you can ensure the efficiency and safety of your fluid system.

Post time: Jan-21-2025