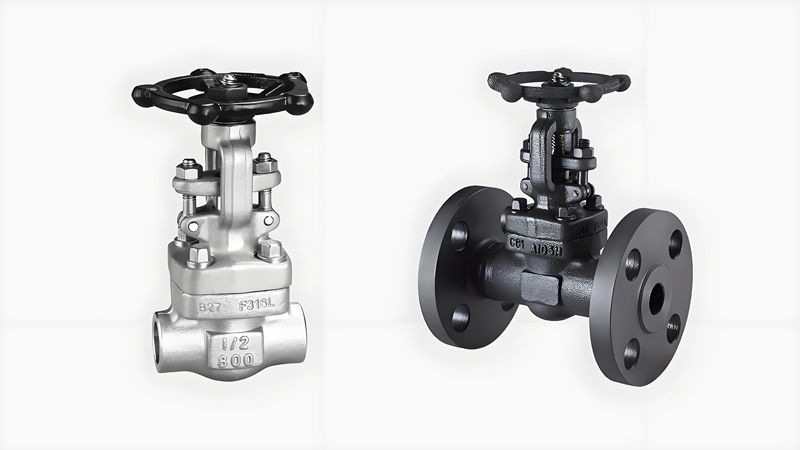

Forged Steel Valve is a valve device made of forged steel material, mainly used for full opening and closing operations. It is suitable for various industrial environments, especially in the pipelines of thermal power plants, and can control the flow of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metal and radioactive media.

Material and Performance

The main materials of forged steel valves include carbon steel, stainless steel, alloy steel, etc. Carbon steel such as ASTM A105/A105N and WCB have good mechanical properties and corrosion resistance; stainless steel such as 304, 316, and 316L are suitable for corrosive media; alloy steel such as A182 F11 and A182 F22 are suitable for high temperature and high pressure environments; high temperature alloy steel such as A182 F91 and A182 F92 are suitable for high temperature conditions; tantalum alloys such as Ta10 and Ta2.5 have extremely strong corrosion resistance; nickel-based alloys such as Inconel 625 and Hastelloy C276 are suitable for high temperature and corrosive media.

Valve types of forged steel valves

- Forged Steel Check Valve

- Forged Steel Ball Valves

Application Fields

Forged steel valves are widely used in many industries, including but not limited to:

Petroleum industry: used for oil and gas pipelines, oil storage tanks and various equipment and pipelines in the refining process.

Chemical industry: used to control the flow of various corrosive media.

Electric power industry: control the flow of fluids such as steam and water in the pipelines of thermal power plants.

Metallurgical industry: used to control the flow of liquid metal.

Forged steel valves play an important role in industrial pipeline systems due to their high strength, wear resistance and corrosion resistance.

Post time: Mar-10-2025