Ball valves are among the most widely used valves in industrial and commercial fluid control systems. Their simple design, durability, and reliable sealing make them ideal for applications requiring quick shutoff or flow regulation. Among the various types of ball valves, full port ball valves stand out for their unique design and performance advantages. In this article, we’ll explore what a full port ball valve is, how it differs from reduced port valves, its key functional characteristics, and its most common applications.

What is a Ball Valve

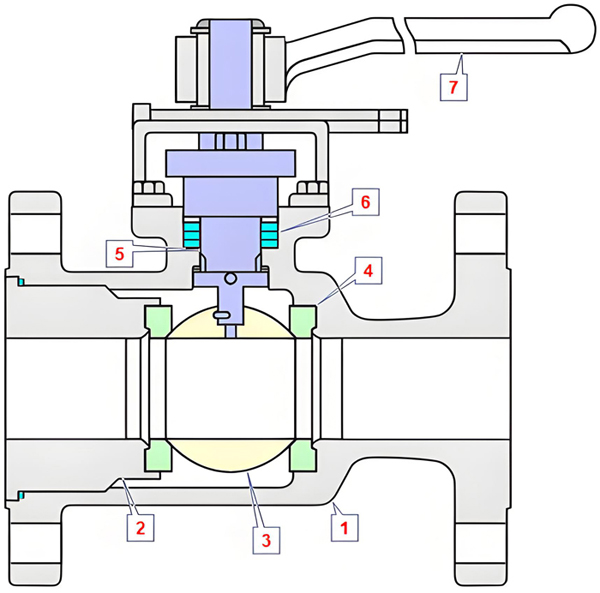

A ball valve is a quarter-turn valve that uses a hollow, rotating ball with a bore (hole) through its center to control fluid flow. When the valve is open, the bore aligns with the pipeline, allowing fluid to pass through. Rotating the ball 90 degrees using a handle or actuator closes the valve, blocking the flow. Ball valves are known for their:

- Quick operation (open/close in seconds).

- Bidirectional sealing (flow can move in either direction).

- Low pressure drop when fully open.

- Durability in high-pressure or high-temperature environments.

Ball valves are categorized by port size, design, and material. The port size—referring to the diameter of the bore—plays a critical role in determining the valve’s flow capacity and pressure drop.

What is a Full Port Ball Valve

A full port ball valve (also called a full bore ball valve) is designed with a bore diameter that matches the inner diameter (ID) of the connecting pipeline. For example, if the valve is installed in a 4-inch pipeline, the bore of a full port ball valve will also measure 4 inches. This design eliminates flow restrictions, ensuring minimal pressure drop and maximum flow efficiency.

Key Features of Full Port Ball Valves:

- Bore Size: Matches the pipeline’s inner diameter.

- Body Design: Larger valve body compared to reduced port valves to accommodate the full-sized ball.

- Flow Efficiency: Nearly zero pressure loss when fully open.

- Applications: Ideal for systems requiring unrestricted flow or pigging (cleaning/maintenance).

Full Port Ball Valve vs. Reduced Port Ball Valve

The primary difference between full port and reduced port ball valves lies in their bore size:

| Feature | Full Port Ball Valve | Reduced Port Ball Valve |

|---|---|---|

| Bore Diameter | Matches pipeline ID (e.g., 4″ valve = 4″ ID) | Smaller than pipeline ID (e.g., 4″ valve = 3″ ID) |

| Pressure Drop | Minimal to none | Higher due to flow restriction |

| Flow Capacity | Maximum | Reduced by 20–50% |

| Valve Size & Weight | Larger and heavier | Compact and lightweight |

| Cost | Higher | Lower |

| Applications | High-flow, pigging, slurries | General-purpose, cost-sensitive systems |

When to Choose Full Port Ball Valves:

- Systems requiring unrestricted flow (e.g., fire protection, water supply).

- Pipelines that need pigging (cleaning devices passed through the line).

- Handling viscous fluids, slurries, or abrasive media.

When to Choose Reduced Port Valves:

- Budget-conscious projects with moderate flow requirements.

- Systems where space or weight is a constraint.

Functional Characteristics of Full Port Ball Valves

1. Zero Flow Restriction

The full-sized bore ensures fluid flows straight through the valve without turbulence or pressure loss. This is critical in high-flow systems like water distribution or oil pipelines.

2. Pigging Compatibility

Full port valves allow pigs (cleaning or inspection devices) to pass through the pipeline without obstruction, making them essential in oil and gas, chemical, and wastewater industries.

3. Bidirectional Sealing

Full port ball valves seal equally effectively in both flow directions, providing flexibility in system design.

4. Durability in Harsh Media

The smooth bore and robust construction (often in stainless steel or alloys) resist erosion from abrasive or corrosive fluids.

5. Easy Maintenance

Many full port valves feature a split-body design, allowing easy access to internal components for cleaning or repairs.

What is a Full Port Ball Valve Used For

Full port ball valves are deployed in industries where flow efficiency, pigging, or media compatibility are priorities:

1. Oil & Gas Pipelines

- Transporting crude oil, natural gas, or refined products.

- Enabling pigging for pipeline inspection and maintenance.

2. Water & Wastewater Systems

- Municipal water supply networks.

- Slurry handling in sewage treatment plants.

3. Chemical Processing

- Transferring viscous or abrasive chemicals (e.g., polymers, acids).

4. Fire Protection Systems

- Ensuring maximum water flow during emergencies.

5. Power Generation

- Cooling water systems in nuclear or thermal plants.

6. Marine & Shipbuilding

- Fuel transfer and ballast water management.

Conclusion

A full port ball valve is a high-performance valve designed for systems demanding unrestricted flow, pigging capability, and minimal pressure loss. While it is larger and costlier than a reduced port valve, its advantages in critical applications—such as oil pipelines, fire protection, and slurry handling—make it indispensable. By understanding the differences between full port and reduced port ball valves, engineers and operators can select the right valve to optimize efficiency, reduce operational costs, and extend system lifespan.

Post time: Mar-23-2025