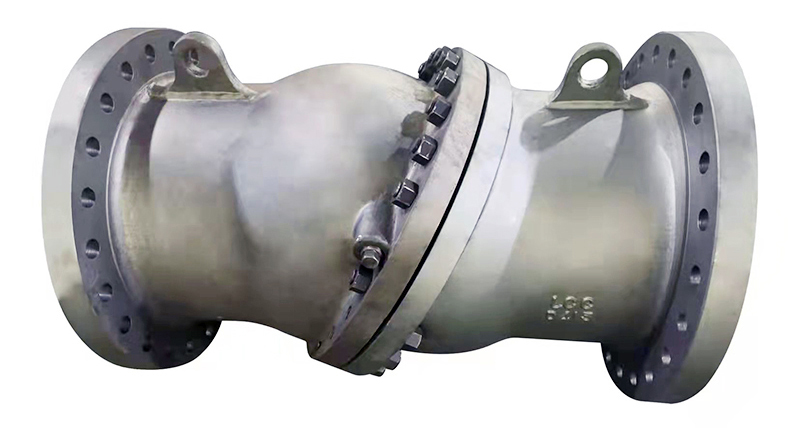

What is a Tilting Disc Check Valve

A Tilting Disc Check Valve is a specialized type of check valve designed to prevent backflow in piping systems. It features a disc that pivots on a hinge or trunnion, allowing it to tilt open under forward flow and quickly close when flow reverses. This design minimizes pressure drop, reduces water hammer, and ensures reliable performance in high-pressure or high-velocity applications such as water treatment, oil and gas, and power generation.

Tilting Disc Check Valve vs. Dual Plate Check Valve

While both valves prevent backflow, key differences exist:

1. Design: Tilting Disc Check Valves use a single pivoting disc, whereas Dual Plate Check Valves employ two spring-loaded half-discs that close like a clamshell.

2. Response Time: Tilting disc valves close faster due to their weighted disc design, reducing slam risk. Dual plate valves rely on springs for closure.

3. Pressure Drop: Tilting disc valves have a lower pressure drop compared to dual plate valves, which may restrict flow more due to their split disc structure.

4. Applications: Tilting disc valves excel in high-pressure systems, while dual plate valves are ideal for compact spaces and moderate pressures.

Tilting Disc Check Valve vs. Swing Check Valve

Swing Check Valves are another common type, but they differ significantly:

1. Disc Movement: Swing valves use a disc that swings freely on a hinge, often leading to slower closure and potential water hammer. Tilting disc valves close more rapidly with a controlled tilting motion.

2. Sealing: Tilting disc designs provide tighter sealing due to the disc’s offset pivot point, reducing leakage risks.

3. Space Requirements: Swing check valves need more installation space, while tilting disc valves are more compact.

Advantages of Tilting Disc Check Valves

- Rapid Closure: Minimizes water hammer and system damage.

- Low Pressure Loss: Optimized flow path ensures efficiency.

- Durability: Robust construction suits high-pressure and high-temperature environments.

- Versatility: Works in horizontal and vertical pipelines.

Choosing a Tilting Disc Check Valve Manufacturer

When sourcing a Tilting Disc Check Valve, partnering with a reputable Tilting Disc Check Valve Manufacturer ensures quality and reliability. China Tilting Disc Check Valve factories are globally recognized for cost-effective solutions without compromising performance. Key factors to consider:

- Certifications: Look for ISO 9001, API, or CE certifications.

- Material Options: Stainless steel, cast iron, or alloy steel for varied applications.

- Customization: Some manufacturers offer bespoke designs for unique system requirements.

Tilting Disc Check Valve Price Considerations

The Tilting Disc Check Valve Price varies based on size, material, and pressure rating. While China-based manufacturers often provide competitive pricing, ensure valves meet international standards for longevity and safety.

Final ThoughtsTilting Disc Check Valves are indispensable for modern fluid control systems, offering superior performance over traditional alternatives. By selecting a trusted Tilting Disc Check Valve Factory, industries can enhance operational efficiency while reducing maintenance costs. Explore options from leading China Tilting Disc Check Valve suppliers to find the perfect balance of quality and affordability.

Post time: Mar-21-2025