What is A Triple Offset Butterfly Valve: the differences between concentric and high-performance butterfly valves

In the field of industrial valves, butterfly valves are widely used in fluid control due to their compact structure and rapid opening and closing. With the development of technology, the design of butterfly valves has been continuously optimized, resulting in multiple types such as centerline butterfly valve, double eccentric butterfly valve and triple eccentric butterfly valve. This article will start from the structural principle, performance comparison and selection recommendations, deeply analyze the core advantages of triple eccentric butterfly valve, and explore how to choose high-quality butterfly valve manufacturers and suppliers.

Classification and Structural Characteristics of Butterfly Valves

1. Concentric Butterfly Valve

- Structural features: The valve plate is coaxial with the valve stem, the sealing surface is symmetrically designed, and the valve seat is usually made of soft material (such as rubber).

- Advantages: Low cost, simple structure, suitable for low pressure and normal temperature conditions.

- Disadvantages: Large friction resistance, and the sealing performance decreases with the increase of temperature and pressure.

- Application scenarios: non-harsh working conditions such as water treatment, HVAC, etc.

2. Double Eccentric Butterfly Valve

- Structural features:

- First eccentricity: the valve stem deviates from the center of the valve plate to reduce the friction of opening and closing.

- Second eccentricity: the valve plate sealing surface deviates from the center line of the pipeline to achieve non-contact sealing.

- Advantages: small opening and closing torque, better sealing performance than the centerline butterfly valve.

- Disadvantages: the sealing material is prone to aging under high temperature and high pressure.

- Application scenarios: medium and low pressure pipelines in petroleum and chemical industries.

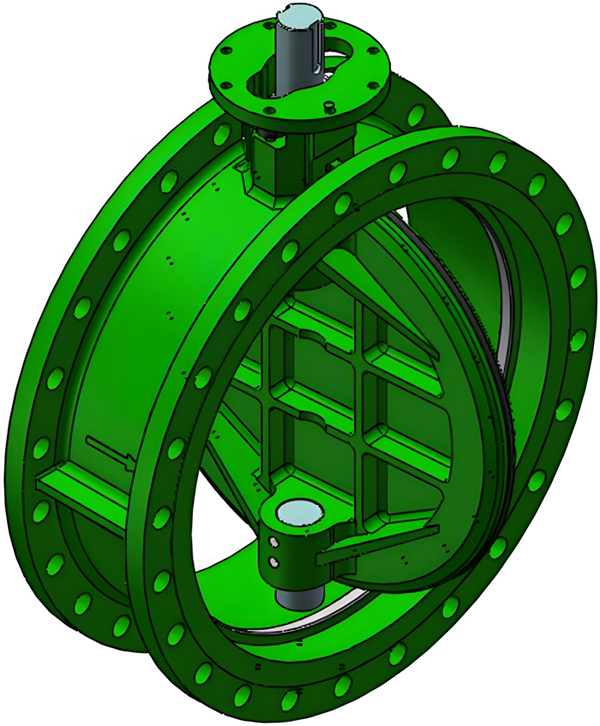

3. Triple Eccentric Butterfly Valve

- Structural features:

- First eccentricity: the valve stem deviates from the center of the valve plate.

- Second eccentricity: the valve plate sealing surface deviates from the center line of the pipeline.

- Third eccentricity: the sealing surface cone angle design achieves metal hard sealing.

- Advantages:

- Zero friction opening and closing: The valve plate and the valve seat are in contact only when closed, which prolongs the service life.

- High temperature and high pressure resistance: Metal seals can withstand high temperatures above 400℃ and Class 600 pressure levels.

- Bidirectional sealing: Suitable for harsh working conditions where the medium flows in both directions.

- Application scenarios: Key systems with high temperature and high pressure such as power, petrochemical, and LNG.

4. High Performance Butterfly Valve

- Definition: Usually refers to a butterfly valve with a double eccentric or triple eccentric structure, which has the characteristics of low torque, high sealing and long life.

- Core advantages: It can replace some gate valves and ball valves and reduce the cost of pipeline systems.

Why is the triple eccentric butterfly valve the first choice for industry

1. Analysis of structural advantages

- Metal hard seal design: Made of stainless steel, alloy steel and other materials, it is corrosion-resistant and wear-resistant.

- Conical sealing surface: progressive contact is formed when closing, and the seal is tighter.

- Fire safety design: some models meet API 607 fireproof certification and are suitable for hazardous environments.

2. Comparison with double eccentric butterfly valve

| Parameter | Double eccentric butterfly valve | Triple eccentric butterfly valve |

| Sealing form | Soft seal or semi-metal seal | All-metal hard seal |

| Temperature range | -20℃~200℃ | -196℃~600℃ |

| Pressure level | Class 150 or less | Highest Class 600 |

| Service life | 5-8 years | More than 10 years |

| Price | Lower | Higher (but better cost performance) |

3. Industry application cases

- Power industry: used in boiler feed water system, resistant to high temperature steam.

- Petrochemical: Control corrosive media in catalytic cracking units.

- LNG storage and transportation: Maintain sealing reliability under ultra-low temperature conditions.

How to choose high-quality butterfly valve manufacturers and suppliers

1. Look at technical strength

- Patents and certifications: Prioritize manufacturers that have patented triple-eccentric butterfly valve technology and are certified by API 609 and ISO 15848.

- Customization capabilities: Can you provide valves with non-standard sizes and special materials (such as Monel, Inconel).

2. Look at production quality control

- Material testing: Material reports (such as ASTM standards) are required.

- Performance testing: Including sealing tests and life cycle tests (such as 10,000 openings and closings without leakage).

3. Look at the price and delivery capability

- Advantages of Chinese factories:

- Price competitiveness: Chinese butterfly valve suppliers rely on large-scale production, and the price is 30%-50% lower than that of European and American brands.

- Fast delivery: Sufficient inventory of standard products, supporting 2-4 weeks of delivery.

4. Look at after-sales service

- Provide on-site installation guidance, regular maintenance and spare parts supply.

Future trends of three-eccentric butterfly valves

1. Intelligent upgrade: Integrated sensors and IoT modules to monitor valve status in real time.

2. Environmentally friendly material application: Adopt leak-free design and low fugitive emissions (ISO 15848 certification).

3. Ultra-low temperature field expansion: Applicable to extreme working conditions such as liquid hydrogen (-253℃) and liquid helium.

Conclusion

Triple eccentric butterfly valve has become the preferred valve for high-temperature and high-pressure industrial pipelines with its revolutionary metal hard seal structure and ultra-long service life. Whether comparing the performance advantages with double eccentric butterfly valve or distinguishing the application scenarios with centerline butterfly valve, it is crucial to choose a butterfly valve manufacturer with reliable technology and reasonable price. Butterfly valve factories in China are becoming the core base for global procurement with their mature technology chain and cost advantages. If you want to know more high-performance butterfly valve technical parameters or get a quote, please contact us – a professional valve solution provider!

Post time: Feb-18-2025