A pneumatic actuator is an actuator that uses air pressure to drive the opening, closing or regulating of a valve. It is also called a pneumatic actuator or a pneumatic device. Pneumatic actuators are sometimes equipped with certain auxiliary devices. Commonly used ones are valve positioners and handwheel mechanisms. The function of a valve positioner is to use the feedback principle to improve the performance of the actuator so that the actuator can achieve accurate positioning according to the control signal of the controller. The function of the handwheel mechanism is to use it to directly operate the control valve to maintain normal production when the control system fails due to power outage, gas outage, no output of the controller or failure of the actuator.

Working Principle of Pneumatic Actuator

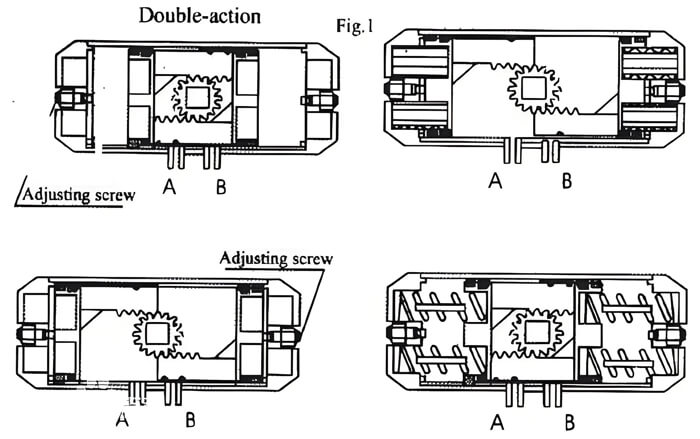

When compressed air enters the pneumatic actuator from nozzle A, the gas pushes the double pistons to move linearly toward both ends (cylinder head ends), and the rack on the piston drives the gear on the rotating shaft to rotate 90 degrees counterclockwise, and the valve is opened. At this time, the gas at both ends of the pneumatic actuator is discharged from nozzle B. On the contrary, when compressed air enters the two ends of the pneumatic actuator from the B nozzle, the gas pushes the double piston to move linearly in the middle, and the rack on the piston drives the gear on the rotating shaft to rotate 90 degrees clockwise, and the valve is closed. At this time, the gas in the middle of the pneumatic actuator is discharged from the A nozzle. The above is the transmission principle of the standard type. According to user needs, the pneumatic actuator can be installed with a transmission principle opposite to the standard type, that is, the selected axis rotates clockwise to open the valve, and rotates counterclockwise to close the valve. The A nozzle of the single-acting (spring return type) pneumatic actuator is the air inlet, and the B nozzle is the exhaust hole (the B nozzle should be installed with a muffler). The A nozzle inlet opens the valve, and the spring force closes the valve when the air is cut off.

Performance of Pneumatic Actuator

1. The rated output force or torque of the pneumatic device should comply with international and customer regulations

2. Under no-load conditions, the cylinder is input with the air pressure specified in “Table 2″, and its movement should be smooth without jamming or creeping.

3. Under the air pressure of 0.6MPa, the output torque or thrust of the pneumatic device in both the opening and closing directions shall not be less than the value indicated on the pneumatic device nameplate, and the action shall be flexible, and no permanent deformation or other abnormal phenomena shall occur in any part.

4. When the sealing test is carried out with the maximum working pressure, the amount of air leaking from each back pressure side shall not exceed (3+0.15D)cm3/min (standard state); the amount of air leaking from the end cover and output shaft shall not exceed (3+0.15d)cm3/min.

5. The strength test is carried out with 1.5 times the maximum working pressure. After maintaining the test pressure for 3 minutes, the cylinder end cover and static sealing parts are not allowed to have leakage and structural deformation.

6. The number of action life, the pneumatic device simulates the action of the pneumatic valve. Under the condition of maintaining the output torque or thrust capacity in both directions, the number of opening and closing operations shall not be less than 50,000 times (one opening-closing cycle).

7. For pneumatic devices with buffer mechanisms, when the piston moves to the end position of the stroke, impact is not allowed.

Advantages of Pneumatic Actuators

1. Accept continuous gas signals and output linear displacement (after adding an electric/gas conversion device, it can also accept continuous electrical signals). Some can output angular displacement after being equipped with a rocker arm.

2. There are positive and negative action functions.

3. The moving speed is high, but the speed will slow down when the load increases.

4. The output force is related to the operating pressure.

5. High reliability, but the valve cannot be maintained after the air source is interrupted (it can be maintained after adding a position-keeping valve).

6. It is inconvenient to realize segmented control and program control.

7. Simple maintenance and good adaptability to the environment.

8. Large output power.

9. It has explosion-proof function.

In Summery

The installation and connection dimensions of pneumatic actuators and valves are designed according to international standards ISO5211, DIN3337 and VDI/VDE3845, and can be interchanged with ordinary pneumatic actuators.

The air source hole conforms to NAMUR standard.

The bottom shaft assembly hole of the pneumatic actuator (conforming to ISO5211 standard) is double square, which is convenient for linear or 45° angle installation of valves with square rods.

Post time: Feb-16-2025