An Actuator Valve is a valve with an integrated actuator, which can control the valve by means of electrical signals, air pressure signals, etc. It consists of valve body, valve disc, valve stem, actuator, position indicator and other components.

The actuator is a very important component of the actuator. Before understanding the actuator valve, we need to know the actuator first.

What is An Actuator

Actuator Definition

Actuator is an important part of automation control technology tools. The following is a detailed explanation of actuators.

What is the Type of Actuators

Actuators can be divided into three categories according to their energy form: pneumatic, hydraulic, and electric.

Electric Actuator

The electric actuator has a motor and a conversion mechanism inside. The motor converts rotary motion into linear motion through gear transmission, pushing the valve stem up and down, thereby controlling the opening degree and flow rate of the valve.

Electric actuators have the advantages of compact structure, convenient operation, high control accuracy, and are easy to integrate with computer control systems to achieve remote control and automated management.

Pneumatic Actuators

Pneumatic actuators are another common type of actuators that accept pneumatic signals and convert them into mechanical motion.

Pneumatic actuators are widely used in pneumatic control valves in industrial production. They accept control signals of 20\~100kPa and drive valves to open, close or adjust. Pneumatic actuators have the advantages of fast response speed, high reliability and easy maintenance. They are particularly suitable for occasions that require fast response and stable control.

Hydraulic Actuators

Hydraulic actuators transmit power through the hydraulic system. The hydraulic station provides pressure oil, which is transmitted to the actuator through the oil pipeline to drive the valve or other mechanical equipment. Hydraulic actuators are usually equipped with electro-hydraulic servo valves, which can achieve precise position control and force control.

Hydraulic actuators are suitable for occasions that require large thrust or torque, such as large valve control, heavy machinery and equipment drive, etc. Due to its large thrust and high stability, hydraulic actuators are often used in industrial applications that require high reliability and high thrust.

After mastering the knowledge of actuators, let’s learn about the relevant knowledge of actuator valves.

The Definition and Function of Actuator Valves

The actuator valve automatically adjusts the opening and closing state of the valve by receiving external control signals, thereby achieving precise control of parameters such as flow, pressure, and temperature. It is widely used in industrial automation control systems to improve production efficiency and production safety.

Actuator valves can be divided into three categories according to different driving methods: pneumatic actuator valves, hydraulic actuator valves, and electric actuator valves.

Pneumatic Actuator Valves

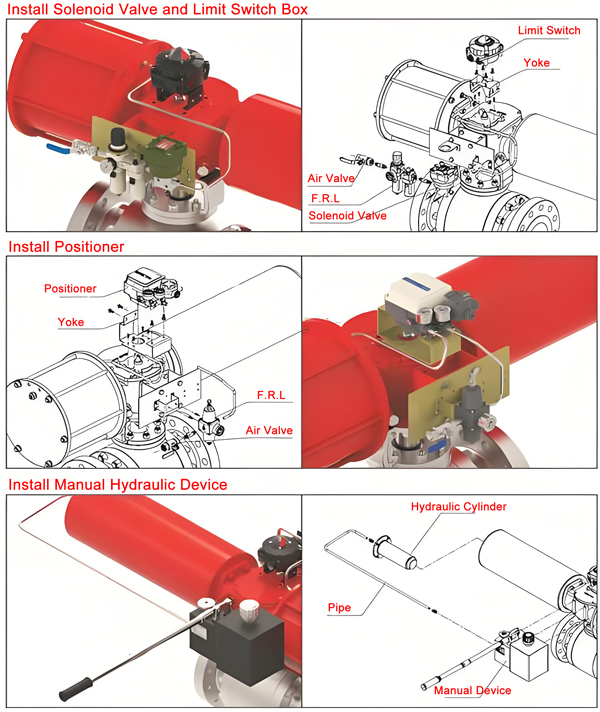

Pneumatic actuator valves are valves driven by pneumatic actuators. They are driving devices for opening and closing pneumatic series angle-stroke valves such as Pneumatic Ball Valves, Pneumatic Butterfly Valves, Pneumatic Gate Valves, Pneumatic Globe Valves, pneumatic diaphragm valves, and pneumatic regulating valves. They are ideal devices for realizing remote centralized or individual control of industrial automation pipelines.

Electric Actuator Valves

Electric actuator valves are valves driven by electric actuators. They are divided into multi-turn, partial-turn, straight-through, and angle-through types.

Multi-turn actuators: used for gate valves, stop valves, and other valves that require multiple rotations of the handle for opening and closing, or drive butterfly valves, ball valves, plug valves, and other partial-turn valves through worm gear drives.

Partial-turn actuator: used for butterfly valves, ball valves, plug valves, etc., which can be opened and closed by rotating 90 degrees

Straight-through actuator: used for valves whose actuator drive shaft and valve stem are in the same direction

Angle-through actuator: used for valves whose actuator drive shaft and valve stem are perpendicular

Hydraulic Actuator Valves

Hydraulic actuator valves is a valve drive device that uses hydraulic transmission as power. Its notable feature is large thrust, but it is bulky and suitable for specific occasions that require large thrust.

Control Valves

Pneumatic actuator valves, Hydraulic actuator valves, and Electric actuator valves are all Control valves. Control valves can also be subdivided into SDV (Shutdonw valves) and Regulating Valves.

Post time: Feb-15-2025