What is HIPPS

HIPPS (High Integrity Pressure Protective System) serves as a critical safety barrier in hazardous industrial environments. This engineered safety system automatically isolates equipment when pressure exceeds safe limits, preventing catastrophic failures.

Key Functions of HIPPS Technology

- Real-time Pressure Monitoring: Continuously tracks pipeline pressure using SIL-2 certified transmitters

- Automatic Shutdown: Triggers ESDV (Emergency Shutdown Valves) within ≤2 seconds response time

- Dual Safety Layers: Implements 2oo3 voting logic with fail-safe redundancy

- Manual Override: Provides emergency shutdown capability through MATRIX PANEL interfaces

Primary Applications of HIPPS

1. Offshore oil platforms (FPSO/WHP installations)

2. High-pressure natural gas transmission pipelines

3. Petrochemical plants handling volatile substances

4. High-risk chemical processing facilities

HIPPS System Architecture: SIL-3 Certified Design

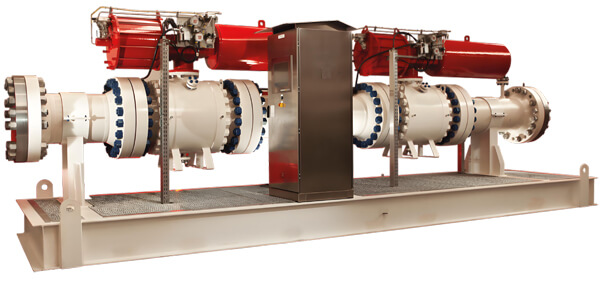

Core Components

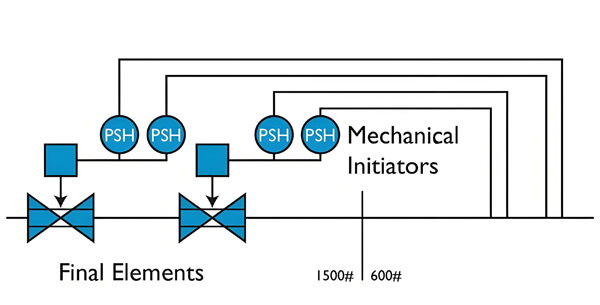

- Triple Redundant Sensors: 3 pressure transmitters with 2oo3 voting logic

- Safety Logic Controller: SIL-3 certified processors (HIMA/Yokogawa ProSafe-SLS)

- Final Elements:

– Dual ESDV/SDV valves in series configuration

– Spring-return pneumatic actuators with quick exhaust valves

– Pneumatic control systems with dual solenoid valves

Technical Specifications

| Component | Certification | Response Time | Key Features |

| Logic Solver | SIL-3/TUV AK6 | <100ms | Solid-state reliability |

| Safety Valves | SIL-4 | ≤2s | Axial flow/Labyrinth design |

| Transmitters | SIL-2 | <500ms | 2oo3 voting logic |

HIPPS vs Traditional Protection Systems

While conventional ESD (Emergency Shutdown Systems) focus on general process shutdowns, HIPPS specifically addresses overpressure scenarios through:

- Higher SIL certification requirements (SIL-3 vs SIL-2)

- Specialized ultra-high pressure valve designs

- Dedicated pressure control logic algorithms

- Integrated test/maintenance bypass functions

Leading HIPPS Component Suppliers

- Controllers: HIMA, Yokogawa ProSafe-SLS, TRICON

- ESDV Valves: Mokveld RZD-X-SAV, PIBIVIESSE, NSW Valve

- Actuators: NSW Valve, Emerson G-Series, Rotork IQ3

- Instrumentation: Yokogawa EJA530 Transmitters

Compliance & Standards

HIPPS systems adhere to:

- IEC 61511 Functional Safety Standards

- ATEX/EExdⅡAT3 Explosion Protection

- IP65 Environmental Sealing

- API 6D Valve Specifications

NSW VALVE: Your Trusted Partner for HIPPS Solutions

NSW VALVE specializes in delivering SIL-3/SIL-4 certified HIPPS systems, ESD valves (ESDV), and safety shutdown solutions (SDV) for high-risk industrial applications. With 20+ years of expertise, we provide end-to-end HIPPS integration – from IEC 61511-compliant design to emergency valve maintenance – ensuring unmatched safety and operational continuity.

Why Choose NSW VALVE

✅ HIPPS Expertise: Full-scope solutions including logic controllers, safety shut-off valves (ESDV/SDV), actuators, and SIL-2/3 instrumentation

✅ Certified Compliance: Components meet ATEX, IEC 61511, and API 6D standards

✅ Proven Partnerships: HIMA, Yokogawa, and Mokveld HIPPS technologies

✅ Rapid Response: ≤2s valve closure systems with 24/7 global technical support

Serving offshore platforms, LNG pipelines, and chemical plants worldwide, NSW VALVE combines engineering precision with field-proven reliability. Our HIPPS systems prevent overpressure incidents with 99.99% operational accuracy, reducing unplanned downtime by up to 60%.

Request a HIPPS Risk Assessment Today – Optimize safety while cutting maintenance costs.

Post time: Mar-26-2025