As a source ball valve manufacturers integrating R&D, design, production and sales, we can ensure that the performance of each ball valve is qualified. The ball valves produced by our company are widely used in oil, natural gas, chemical, seawater, shipbuilding and other fields, and have been recognized and praised by customers. We have also obtained the certificates ISO 9001, ISO14001, CE-PED, API6D, API 6FA, API 607, SIL3, ATEX, ISO15848-1, etc.

Selection of Industrial Ball Valve types

Ball valve manufacturer NSW is committed to manufacturing ball valves that can be perfectly applied to various harsh working conditions, including Cryogenic (-196℃), high temperature, high pressure, vacuum (negative pressure). It can also be used for fluid pipelines of acids, alkalis and special media that are easy to crystallize and easy to eroded.

Upgrade your safety system with our emergency shutdown valves (ESDVs) and SDVs, designed to provide rapid response in emergency situations.

Choose our Segment Ball Valve, V Notch Ball Valve, and Control Ball Valve for innovative designs that provide exceptional flow management and efficiency.

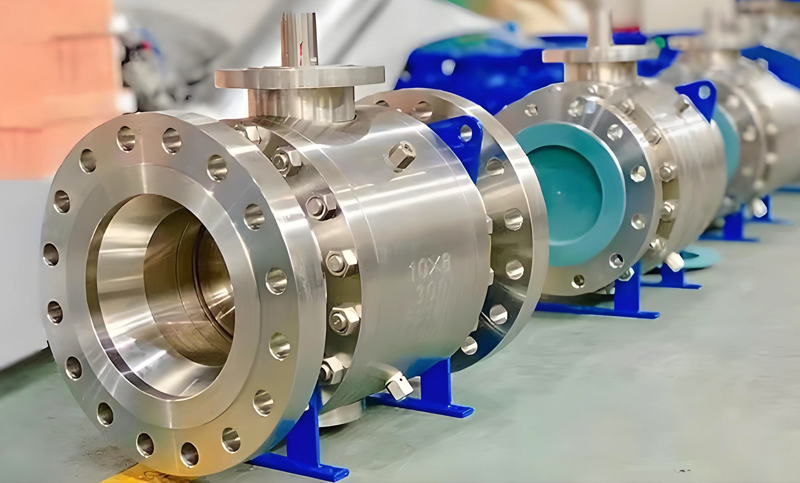

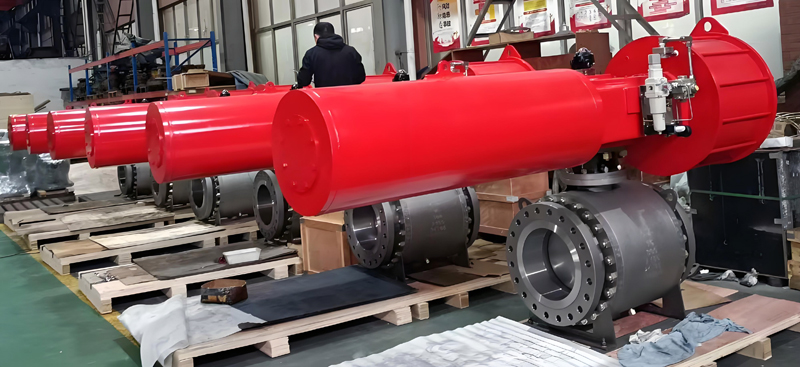

Discover high-quality fully welded ball valves for natural gas pipelines designed for durability and efficiency. Ideal for reliable gas flow control in a variety of applications.

NSW High-quality Double Block and Bleed Ball Valves designed for optimal performance and safety. Suitable for a wide range of industrial applications, ensuring reliable operation and preventing leakage.

Upgrade your plumbing system with our L-type and T-type Three-way Ball Valves. These valves are designed to be precise and reliable, suitable for any oil, gas and chemical project.

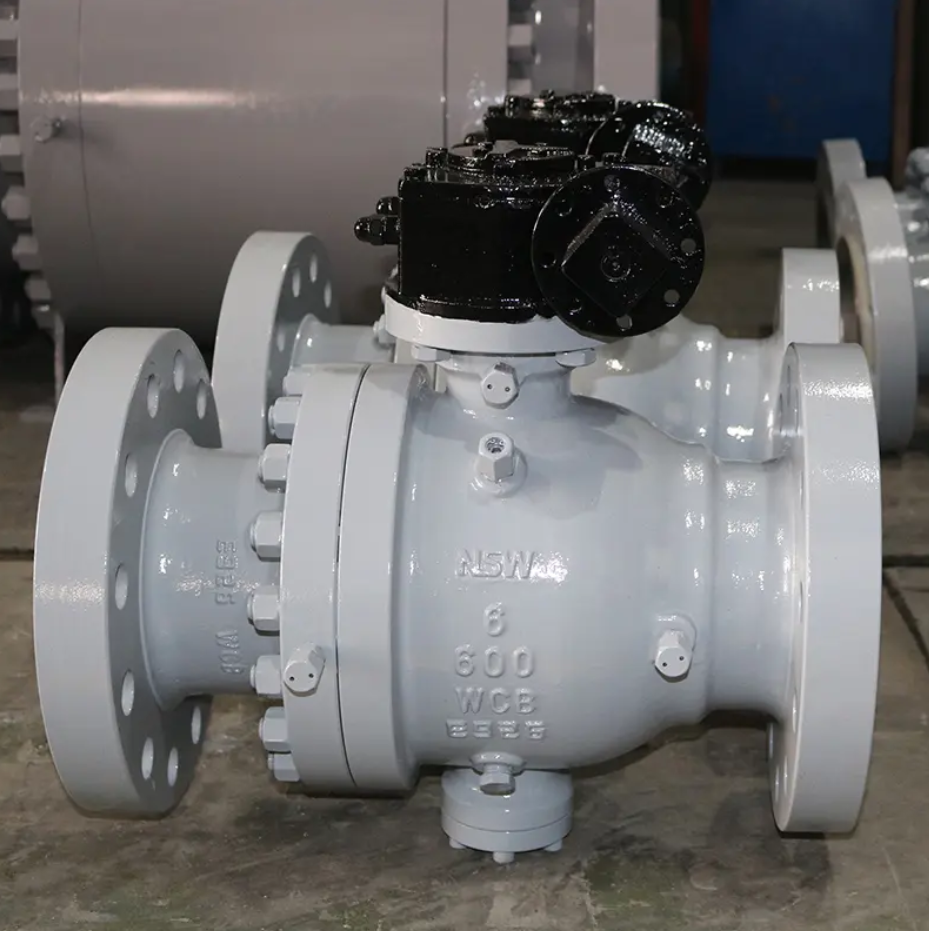

Purchase excellent Top Entry Ball Valves from ball valve manufacturer, it made from carbon steel and stainless steel to ensure strength and efficiency for your industrial needs.

Explore our selection of Stainless Steel Ball Valve Class 150 in CF8 and CF8M, ideal for enhancing efficiency and safety in your piping systems.

Enhance piping system with Floating Ball Valve Side Entry, offering reliable performance and installation. Ideal for commercial and residential projects.

To know our durable Carbon Steel Ball Valves featuring flange design and Trunnion Mounting for optimal performance in a variety of applications.

How to Control the Quality of Ball Valve

Controlling the quality of ball valves requires strengthening control from aspects such as supply chain management, production process control, inspection system and after-sales service to ensure that product quality meets standards and customer needs.

Choose A Suitable Ball Valve Supplier:

First of all, you should choose a ball valve supplier with good reputation and rich experience. When choosing a supplier, you should strictly review its qualifications, production equipment and process level. NSW will be your partner of China valve manufacturer.

Strictly Control the Quality of Valve Raw Materials:

The materials used in ball valves directly affect their quality. You should choose high-quality raw material suppliers and conduct strict quality inspection and control on the raw materials.

Strengthen Valve Production Process Control:

In the production of ball valves, process control should be strengthened, and operations should be strictly carried out in accordance with process regulations to ensure strict control of each link to prevent quality risks caused by improper operation.

Improve the Valve Quality Inspection System:

After the production of ball valves is completed, comprehensive and detailed quality inspections should be carried out. The inspection equipment should be advanced and accurate, and the inspection methods should be strictly operated in accordance with standards.

Strengthen Valve Factory After-sales Service:

The quality issues raised by customers should be responded to quickly, the quality issues that arise should be solved in a timely manner, and products and services should be actively improved to continuously improve customer satisfaction.

How can you Choose the Correct Ball Valves

There are many types of ball valves. It is a widely used valve that is often used to control and cut off liquid flow. It is very important to choose the correct ball valves. Let's listen to the advice of China Ball Valve Factory - NSW

Selection of ball valve structure:

Floating Ball Valve:

The ball of the ball valve is floating. Under the action of the medium pressure, the ball can produce a certain displacement and press tightly on the sealing surface of the outlet to ensure the sealing of the outlet. Commonly used for ball valves below 8".

Trunnion Mounted Ball Valve:

Compared with the floating ball valve, when it is working, the force generated by the fluid pressure in front of the valve on the ball is all transmitted to the bearing, and the ball will not move toward the valve seat, so the valve seat will not bear excessive pressure. Therefore, the fixed ball valve has small torque, small seat deformation, stable sealing performance, long service life, and is suitable for high pressure and large diameter occasions.

Two Piece Ball Valve

It consists of a left valve body and a right valve body. Usually, cast ball valves will adopt a two-piece structure, such as WCB ball valve, CF8 ball valve, CF8M ball valve, etc. The production cost will be lower than that of forged ball valves.

Three Piece Ball Valve

The three piece ball valve is usually composed of a valve body, a ball and a valve stem. The valve body is divided into three pieces, and the ball rotates in the valve body to achieve the switch function.

The three-piece ball valve is mainly used in the pipeline to cut off, distribute and change the flow direction of the medium.

Side Entry Ball Valve

The inlet and outlet of the ball of the side entry ball valve are located on the side of the valve body, and the ball rotation axis is perpendicular to the pipeline axis

Top Entry Ball Valve

The ball of the top entry ball valve is located on the upper part of the valve. This design allows the internal components to be replaced and maintained without disassembling the pipeline, greatly reducing maintenance time and cost.

Modular design: Key components such as the ball, valve seat and seal can be quickly disassembled and replaced.

Low operating torque: The contact area between the ball and the valve seat is small, and the operating torque is low.

Self-cleaning characteristics: The rotation of the ball can scrape off the scale on the valve seat and reduce the obstruction of fluid flow.

Multiple sealing materials: Seals of different materials can be selected according to different media characteristics.

Choice of Ball structure in Ball Valve

Full Port Ball Valve

The valve body channel diameter of the diameter ball valve is equal to the pipeline diameter, that is, the diameter of the ball matches the inner diameter of the pipeline, usually with a lower flow resistance coefficient and a higher flow rate coefficient, which can ensure that the fluid maintains a small pressure loss and a faster flow rate when passing through the valve. In addition, due to the large sealing area between the ball and the valve seat, the sealing performance is relatively good.

Reduced Port Ball Valve

The valve body channel of the reduced diameter ball valve will be reduced to a certain extent before and after the ball, that is, the ball diameter is smaller than the inner diameter of the pipe, with compact structure and light weight. However, it reduces the flow resistance coefficient and flow coefficient to a certain extent, and when it needs to handle high pressure, high temperature or corrosive media, its sealing performance may be affected to a certain extent.

V type Ball Valve

The most notable feature is the use of V The V-shaped (or conical) valve seat design. This design allows the ball to form a gradually changing channel during rotation, thereby achieving precise regulation of the fluid flow. V-type ball valves are usually equipped with manual, electric or pneumatic drive devices to control the rotation angle of the ball. By adjusting the rotation angle of the ball, precise regulation of the fluid flow can be achieved (in this case, it can be called a V-type regulating valve). The V-groove design of the V-type ball valve also has a self-cleaning function. When the fluid passes through, the V-groove can guide the fluid to form a certain flushing force, help remove impurities and particles on the valve seat, and maintain the valve. Clean and unobstructed.

Choice by Multi-way Ball Valves

Straight Through Ball Valve

A straight-through ball valve is a ball valve without any obstruction inside the valve body. It is usually in the shape of a long strip connected by two flanges. Straight-through ball valves are mainly used in situations where the medium flow is large. Because the direct diameter is the same, the medium can flow smoothly regardless of whether the switch state is open or closed.

Three Way Ball Valve

The three way ball valve is a ball valve used for diverting, converging and changing the flow direction of the medium. According to its different structures, the three way ball valve is mainly divided into T type ball valve and L type ball valve. The T type three way ball valve can connect three orthogonal pipelines and cut off the third channel, which is suitable for diverting and converging operations; while the L type three way ball valve can only connect two orthogonal pipelines, and is mainly used for distribution.

Four Way Ball Valve

The 4 Way Ball Valves has two inlets and two outlets. The ball is designed with a complex channel structure inside to achieve cross-flow or diversion and confluence functions of the fluid. The four-way ball valve can flexibly adjust the distribution and mixing of fluids between multiple paths to meet complex process requirements, such as heat exchangers, distributors, mixers and other equipment.

Choice of Ball Valve Actuator Operation

Manual Ball Valve

The ball is driven to rotate by rotating the handle or turbine to control the on and off of the fluid. No external energy is required, and the reliability is high. Suitable for small pipeline systems or occasions that require frequent manual operation.

Pneumatic Actuator Ball Valve

Using compressed air as the power source, the ball is driven to rotate through a pneumatic actuator (such as a cylinder). Pneumatic ball valves are fast and responsive. Suitable for remote control or automated control systems. A handwheel operating mechanism can also be added.

Hydraulic Ball Valve

Using liquids such as hydraulic oil or water as the power source, the ball is driven to rotate through a hydraulic actuator (such as a hydraulic cylinder). The hydraulic ball valve has a large output torque and can drive large-caliber or high-pressure ball valves. Suitable for occasions with high driving torque requirements. A handwheel operating mechanism can also be added.

Electric Actuator Ball Valve

It controls the opening and closing of the ball valve through the electric actuator, thereby achieving control of the medium in the pipeline. The electric ball valve consists of an electric actuator and a ball valve body. By inputting a standard signal, the motor group drives the worm gear angular torque to adjust the valve with a switch box.

Choice Ball Valve by Valve Material

Carbon Steel Ball Valve

Carbon steel ball valve is a kind of ball valve made of carbon steel material, which is a kind of fluid control equipment. It controls the on and off of the fluid by the rotation of the ball.

It is divided into cast steel ball valve and forged carbon steel ball valve. It can also be divided into low carbon steel carbon ball valve, medium carbon steel ball valve, high carbon steel ball valve, etc.

Stainless Steel Ball Valve

Stainless steel valves refer to valves made of stainless steel. Since they are made of stainless steel, they are resistant to corrosion, high temperature and wear, and are widely used in petroleum, chemical, metallurgy, light industry and other industries.

Stainless steel materials are usually classified into cast stainless steel and forged stainless steel.

Cast stainless steel ball valves are made of ASTM A351 CF8, CF8M, CF3 CF3M etc.

Forged stainless steel ball valves are made of ASTM A182 F304, F316, F304L, F316L etc.

Duplex Stainless Steel Ball Valve

Duplex stainless steel ball valve is a ball valve made of duplex stainless steel material, mainly used for pipelines containing Cl⁻ or H₂S media. Its valve body, ball and stem are made of duplex steel materials, such as ASTM A995 4A (CD3MN), 5A (CE3MN), 6A (CD3MWCuN), 1B (CD4MCuN) and other castings or ASTM A182 F51, F60, F53, F55, F61 and other forging materials. we also call it as 4A ball valve, 5A ball valve, F51 ball valve, F55 ball valve etc.

Special Alloy Steel Ball Valve

Special alloy steel ball valve refers to a ball valve made of special alloy steel material, which is mainly used in highly corrosive, high temperature or high pressure conditions. Special alloy steel ball valve has excellent corrosion resistance, mechanical strength and sealing performance, and is widely used in chemical, petroleum, natural gas, power and marine engineering fields.

- C4 ball valve

- Aluminum bronze ball valve

- Monel ball valve

- Hastelloy ball valve

- Titanium alloy ball valve